Crafting a Successful Cross-Functional Team - Logistics

Overview

In this episode, Bruno Ferreira, the founder of BlueDot Ecommerce, joined Paul Sonneveld and discussed Logistics, the second of the three-part series on how to build the best-in-class cross-functional team for the Amazon Vendor Channel platform.

Complete Transcript of the Podcast

Introduction

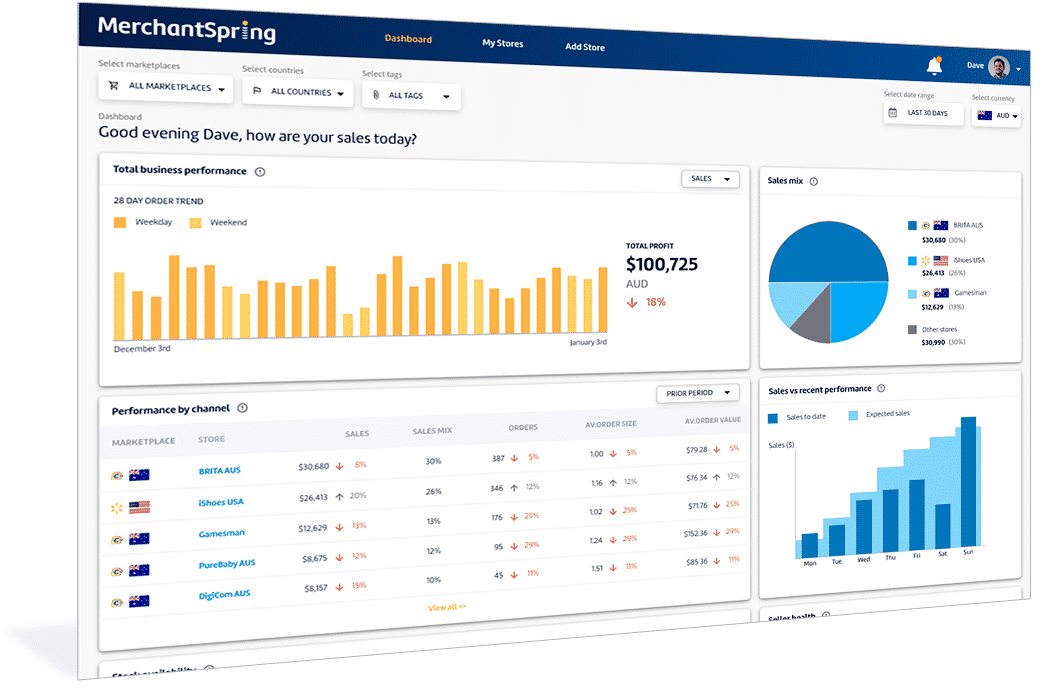

This episode of Marketplace Masters is brought to you by MerchantSpring. Are you an Amazon vendor juggling multiple accounts? Struggling to keep up with performance metrics and endless Excel sheets? Well, it's time to simplify your workload with MerchantSpring, the leading analytics platform for Amazon Vendors helping you stay ahead of the curve and streamline your operations. Head to merchantspring.io today and book a free personalized tour. Discover the muscles of optimized analytics and reporting today.

Hi and welcome everyone to another live episode of Marketplace Masters. Marketplace Masters and this series in particular is really focused on going deeper, quite deep, actually, into the challenges that Amazon vendors face in order to lift performance really via practical insights and actions.

Paul Sonneveld

I'm your host, Paul Sonneveld, and today we will continue our journey to learn how to build the best-in-class cross-functional team for the Amazon vendor Channel. Now, to help us do this, I've actually reinvited Bruno Ferreira to join us and share his expertise again. Some of you will remember him from an episode we did earlier on towards the end of last year. But for those of you who haven't met him, let me just make sure I introduce him properly.

So, Bruno is the founder of BlueDot E-Commerce, a full-service Expert partner for Amazon Vendor Central in-house integrated operations across the entire supply chain from sales to logistics and finance.

Bruno has spent the past seven years specializing in setting up and managing B2B Amazon Vendor Central operations for many Europe-based manufacturers, distributors, companies, and brands for the Amazon global businesses across Europe, The Middle East, India, APAC, Lat Am, and the USA.

So I don't think there's an area of the world that he hasn't covered. So, he certainly brings with him an awesome range of experience to the conversation today. Bruno, it's an absolute pleasure to have you on the show and happy 2023 to you.

Bruno Ferreira

Thank you, Paul. It's great to be here again. Thank you. And the same to you. I think this is going to be a great year. There will be a lot of challenges. I hope we all can help.

Paul Sonneveld

For sure, for sure. Yeah. Look, I'm certainly excited. I love operations. A bit of an operations person at heart. Although I'm by no means an expert. But for those of us listening in and tuning in, just help us set the scene.

You know, we've been focusing on how to build a world-class cross-functional team, SOPs and the like. Just give us a bit of an outline. How does that look from your perspective, the three pillars, and how does today's episode really fit into the broader picture that we're, we're covering as part of this series?

Bruno Ferreira

Yeah. Well, part of my idea and BlueDot vision is through all of these years of experience and all the markets that I helped companies, I started to notice one thing that Companies will get invited to supply for Amazon Vendor Central. It's a great opportunity for brands. They can grow. It's a great window for their products. But I started to notice that there was a lot of help after they started to supply. After they go, they went live.

Amazing work on marketing and advertising and sometimes I've seen this happen a lot of times through all of these years. Companies were not looking with them. They were so proud and correctly to supply for Amazon Vendor Central. But one of the errors, as an example, they will think that whatever SOPs they have from logistics, from what we'll be doing today or even from sales and finance, whatever they have in place, will feed Amazon. And sometimes it's not just like that. It's not as simple as Amazon. It's very specific in their requirement.

For logistics, they have requirements for pick and pack. The way that the inbound team receives the stock in the fulfillment centers. And we see some challenges coming from there if they are not done correctly. My idea is to help companies to check their current SOPs, their standard operating procedures and how can we adapt them if we can or change them or even build new ones. And that will be in the format of a best spoke SOPs that I can see. There is a great help and it's the way to go.

Paul Sonneveld

Sorry to interrupt. Because we'll be talking a lot about SOPs today and cross-functional teams and for those of us who are sort of not living in that terminology on a databases, just can you take maybe 20 seconds, just explain what is an SOP and how does it fit within kind of a cross-functional context, certainly within an Amazon vendor business?

Bruno Ferreira

Yeah, so SOP means Standard Operating Procedures. It's a workflow. It's a step-by-step process to help the teams to get to the target of their functions. From sales, you will have specific tasks. If they are organized in an SOP, it'll be easier for the Sales Manager, the contact, to have more visibility and traceability.

On logistics, those SOPs, of course, are a great tool for the connection between sales and finance. The way they communicate, the step-by-step guidance on how to start the packing of the boxes. What do I do next? Then I need to go to the web interface. I need to submit an ASN. What's an ASN? The cross-functional team Paul, my idea is super important too. We did the previous podcast on the main point of contact of the cross-functional team.

I see a lot of companies that get invited to supply through Amazon Vendor Central, and they feel they don't have the need to hire. So, they usually select someone from the team that probably is doing the web shop, something online. But that point of contact will need to be aware that his job, his workload will be to help managing this cross-functional team. He won't be their manager probably.

But for everything regarding logistics, finance, and sales of Amazon Vendor Central, he will have the visibility and across all the functions, he will be prepared to deal with challenges. So, a strong cross-functional team, trained, aware of the requirements, the processes of Amazon, and then the best spoke SOPs implemented for me, it's the way to go and it'll drive to success for sure.

Paul Sonneveld

Excellent. Well, let's talk about, I know we've got a couple of supporting aids here as well. I'd love to start off with just kind of the theory. In terms of, how does the flow happen from a purchase order all the way to delivery? Maybe take us through, what does that look like?

Bruno Ferreira

Yeah. So, I hope someone is here from the previous podcast. So, we started with the sales. Today we're going to do a logistics. The web interface of vendor central, it's kind of a maze. People need to be trained to be aware of the requirements step by step. What are the tasks. And then, If you guys remember, I see supplying success to supply Amazon Vendor Central sitting on three big pillars, very strong pillars, Sales, Logistics, and Finance. If you notice this is each part of the contact of that cross-functional team.

Today we're going to cover the logistics and see how that efficiency, how that visibility will help with the daily challenges and will help, I hope people not to get so frustrated sometimes with the way of working of Amazon. So, Amazon supplying Amazon Vendor Central. Amazon, as we just mentioned, has very specific requirements.

We start to receive a PO. We have different cycles to receive orders from Amazon, depending on the category. Usually, you'll receive orders on a Monday, Wednesday, and Friday. People with experience know that sometimes they change, and you might receive orders on a Friday at 5:00 PM with a short delivery window.

After that processing, then we'll go to the warehouse and our relationship with the carrier and that will be the focus of today's podcast. And now we can make some wins with the bespoke SOP for logistics. And after that success of course, the finance team will take care of the payments, the deductions, submit the invoices, and all those details.

Paul Sonneveld

And can I just ask Bruno, how much time does Amazon typically allow for a vendor to accept a purchase order? I've heard this terminology in terms of like a soft accept versus a hard accept. Can you shed some light on that?

Bruno Ferreira

Yeah. So when you receive a PO, an order from Amazon, usually the clock starts ticking. Amazon gives 24 hours for the process. Sometimes you will notice that after those 24 hours, the order will still be there for you to process. What you need to keep in mind is that, that will be part in the back end of the algorithm if we can say that it's always recording. So, a quick acceptance or processing of appeal will play in your favor.

Amazon will always select vendors that are quick to process POs and to make the delivery. So if you receive their order on a Monday, so Amazon gives usually between five to seven days as a delivery window. We all know that Amazon orders have a delivery window. If you receive it on a Monday, probably you will have five days, meaning that you will deliver on the Friday.

But if you receive it on Wednesday, you will get two extra days because of the weekend. So, meaning that if you receive their order on a Wednesday, you won't have to deliver it on Friday. You will probably deliver it on Tuesday or Wednesday next week because Amazon is aware of the weekend and takes that into account.

A soft reject can be, you have a few options when you're processing an order. A soft reject might be for different reasons. You add the new item to your catalog, and when you were adding it, you didn't mention, you didn't tell Amazon when it'll be available. I see this happen a lot. You need to tell Amazon, okay, I'm adding this to my catalogue, but it'll only be available from next month. If you are not careful doing that, you might start receiving orders for an item that you still don't have in stock.

A soft reject for that and Amazon is aware, will be not yet in stock. Of course, that will cause is affecting your performance rate. Your acceptance rate will be always measured by Amazon. And Amazon considers above 70% acceptance rate for you to be a good supplier. A hard rejection might be permanently unavailable, out of stock. There are a few different reasons in the dropdown menu individually per PO that you can select.

Paul Sonneveld

That's very interesting. Particularly the 70%. I mean, of course, there's the other side of that which is it's a lost ship COGS opportunity.

Bruno Ferreira

Yeah.

Paul Sonneveld

Amazon wants a stock as well. Great. Very interesting. But let's move on to the meaty part of this, this session, which is really about the SOPs inside the warehouse and the carrier. So yeah, take us through, how you think about designing bespoke SOP for the warehouse.

Bruno Ferreira

Yeah. So, when I start working with the company when we get to the part of the logistics, I have different companies that I've worked. I've worked with companies that ask me to help them to set up from scratch.

Others were already working, but noticed that there was some work to be done. And when I start with the logistics, one of the first things that I start to advise the companies is that there are a few points as per the Amazon requirements that we need to work around.

One of those points is exactly the PO cycle, as I mentioned. If you receive it on a Monday, does your carrier can deliver it here on Friday? What country am I delivering? I'm dispatching from the UK to Spain. Am I allowed to do it? Can my carrier help me with that?

So, we need to be careful in this planning when we can see they're are carrier partner because Amazon, as we all know will always charge us back if we are non-compliant. If you cannot meet the delivery window, Amazon will charge you back a non-time compliance chargeback.

After that, I start to go and help the warehouse teams on site with them. I love to get my visibility best, my security boots, spend time with them. Everybody that knows me knows that my favourite team is always logistics. They are the best to party and they are operation people like us and they're really fun.

Paul Sonneveld

Keep in mind that we do have a Finance session coming up. You know, I know as long as you, by the time we have the finance session, you can, you can say the same about the finance team. I'm sure everyone will be happy. Right?

*(Both laughs)*

Bruno Ferreira

I won't. They know they're that I I like them. But from my experience, logistics, it's those people because people like us that think with the mentality of processes and operations. If you notice that's the warehouse people, sometimes it can be a challenge, and I'm going to give a few examples because sometimes you find people that don't see grey.

You find people that have been working with the company for four years, six years, they always did things like this. But now it needs to be different to Amazon. This is exactly part of the second point, the pick and pack and the Amazon requirements. I am always sensitive when I meet with the warehouse manager and the team to bring them on board.

It's very important to explain them why are we doing these changes. Why do I need now to get the number in the box? Why does this box need to be number one, and this box needs to be number two? And I found from my experience that if you explain to people, if they understand the reason of the change, then they will easily get on board because you need to make them understand why are we making these changes.

Paul Sonneveld

What are some of the most difficult or hardest changes to make in terms of what Amazon expects compared to what a warehouse may be have been doing for other retail partners up until that point? I mean, what are the hardest things to change?

Bruno Ferreira

Well, sometimes Paul, one of the hardest change is the way that we are dispatching the products. Amazon has very specific requirements. I'll give you an example. Recently I worked with a company that got invited to Vendor Central, a very specific product glass bottle with a liquid. When I got on board, they asked me to do some consulting with them to check what was going not so good and could be improved.

One of the things that I first noticed was that they were dispatching that glass bottle in with a liquid and this company was not full ready for e-commerce for online. It means that in their production site, they didn't have direct-to-consumer packaging. Amazon is very, very specific how they receive glass in their fulfillment centers.

They consider it dangerous for their associates in the fulfillment centers. If a bottle breaks, someone can get cut and Amazon wants to receive in a safe way. In glass with liquid, Amazon requirements are even if you have to bubble wrap individually each bottle.

This company that I was helping, we noticed that they were actually dispatching since they didn't have much experience. They were dispatching like they were dispatching to all the other clients. In an SRP packaging. SRP means a shelf-ready package, just a card box in the end with a plastic wrap. It's easy for retail because you just remove the plastic and goes to the shelf. For Amazon, it's a bit different. It's very dangerous. They consider it dangerous. That caused what was the scenario here?

So the scenario here was that they were dispatching and they started to receive the prep-related issues chargebacks, and it's very expensive. It's a fixed chargeback. There's a few fixed chargebacks, and in this case it caused a huge impact in their profit because it was taking 98% of their profit. And what I noticed is that they were not aware of this.

They didn't have the knowledge. The requirements manuals for Amazon are huge. It's a lot of pages with a lot of different rules that you need to go through. And with this strong bespoke SOPs, everything can be minimized. So I helped the company in this situation.

It was a big challenge because as we know, Amazon is not very keen about CPIs. At the time, it'll take some time to come up with direct-to-consumer packaging. But Amazon, if you know how to speak with them, they will listen to you. They will be your partner. So, in this case, we agreed and Amazon allowed it and even help to engage in a new direct-to-consumer packaging so that it'll be safer to deliver to the fulfillment centers.

So there can be a huge impact in this pick and pack process, this part of the SOP, that if the teams are not aware of this, doing the packing, that they need some prep related, individual for the bottles in this case, it'll cause a lot of issues and challenges.

Paul Sonneveld

So there could be some huge hitting costs for not doing this problem?

Bruno Ferreira

Yeah.

Paul Sonneveld

The other thing that strikes me as you were talking about it. You're dealing with people in the warehouse who've probably been doing a job picking and packing things for other channels, other retailers for years seem to be quite a big change management piece potentially required, you know, how do you get them to pick to a new standard?

I haven't even talked about labelling yet, but how do you personally, achieve that change on the floor within kind of the mindset, and changing that might be one of the hardest things to achieve

Bruno Ferreira

It is Paul and, I have a lot of funny stories and challenging stories talking with people, warehouse managers, that were doing the job for 14 years and for 14 years, their job was simple. 14 boxes of this, put it in a pallet, contact the carrier, put the label and dispatch. With Amazon, not exactly like that. You will need to tell Amazon.

Amazon will want to know how many boxes, how many pallets, what's inside each box that I'm receiving, you're sending me two boxes, but I want to know which purchase order number there's it to refer to, and what items are inside? What's the quantity to bring on board people that have been doing a job consistently the same way to do this? It's not easy.

From my experience, I always start with a conversation to understand their side. And as I said in the beginning, I've learned that if people understand the changes and the reason why because sometimes, we try to implement changes and we don't bring people on board. Why are we making these changes? What do I have to gain with it?

Because I've been doing this, and I've been doing it great. I've been in this company for eight years and I've been doing it this way, and now you're asking me to do it slower, to do it differently. What's my part in that? And I explain people, this is a new stage for the company.

It's a new win for the brand. We will grow. It'll take some time. Yes, it'll require a lot of work, but you are part of a key process. You guys will be that part that will avoid eroding margins. That will give the sales department and the finance, the visibility and traceability for any challenges that they will encounter. Just think that every time that a company receives a chargeback, it'll involve the point of contact from finance. That person will have a deduction. It'll cause extra work.

If we can mitigate that extra work in the logistics part with proper training, people understanding what they're doing. Why am I doing, why does Amazon want to dislike this? I've learned that it's a bit easier. But Paul, honestly, it's a lot of fun sometimes, but the fun only comes a few weeks after some strong conversations.

Paul Sonneveld

Yeah, I imagine that tensions can boil over at times particularly if the team feels like they've got into a way of working their KPIs, that their internal KPIs are looking good, and now it just feels like you're just layering complexity and additional process for no additional gain. So I think your point around explaining the picture and their strategic role. Literally, it is in terms of they can make or break the commercials of the channel is very critical.

Bruno Ferreira

They will be Paul like, they will be the bridge directly to Amazon because they are actually, so the sales contact will process the orders. The finance will take care of deductions from payments and all of that work.

But we know that if done correctly, we'll always have chargebacks. There will always be shortage claims, but I strongly believe that bespoke SOPs training and bringing people on board in the warehouse will help a lot to reduce these challenges.

Paul Sonneveld

Yeah, let's talk a little bit about labelling, because I generally pick up a lot of noise around labelling requirements, not getting it right, products getting rejected. Help explain a little bit, what are the difficult things or what are the changes that Amazon is looking for when it comes to labelling and in your experience, what typically goes wrong?

Bruno Ferreira

Well, the labelling part is part of the ASN submission Paul. ASN means Amazon shipment notification. It means that within a single label, we are within a scan the inbound team in the fulfillment center we'll know which POs it refers to the total quantity of boxes, pallets, and what's inside each box. Allow you to that, to each box, you will also have an AMZCC box.

So this AMZCC, it means Amazon container codes or SSCC shipment labelling. The only different from these two is that if you're doing it manual, the AMZCC request on the web interface or the SSCC label are from the EDI transmission, meaning that you are not doing it manually on the web interface.

A lot of companies are moving to EDI. I always advise companies that I work with to try as soon as possible to move to EDI. So that's the only difference. So you will have these two labels per box. If you are dispatching on a pallet, you can ideally, if you are dispatching same product, same PO, you will only have one per pallet.

There are different requirements where I see this fail poll or with room for improvement, is the way that we submit the ASN. So this ASN contains all the details, how many boxes, how many pallets, what's inside each box. And I've seen the warehouse team, if they don't have this SOPs, this guidance line to help them and the proper training to go to the web interface to request the labels and submit the ASN. That's where Samaras can come and the impact will be negative too, because it'll cause chargebacks, delays.

So the resolution for this is training and SOPs. I can give you an example. I worked a few months ago with a company that was having a lot of issues when the inbound team at the fulfillment center were receiving the stock.

The first thing I did was an audit in the chargebacks, and I noticed immediately that the majority of the chargebacks were carton content chargebacks, and ASN-related chargebacks. So immediately that told me I need to get up and go to the warehouse.

So I spent some time with the warehouse. I go to the warehouse. I spend some time with them there and very quick in a couple of hours working with them, I understood what was going wrong. They were not taking in consideration a detail, a very important detail.

*(Encountered some technical issues)*

Paul Sonneveld

I had actually another three questions I want to ask you about the warehouse SOPs, but let's get to that if we have time at the end.

Bruno Ferreira

Yeah. Okay.

Paul Sonneveld

Let's move to the carrier side of things and the SOPs there. Obviously, that's the other part of this whole equation, right? You can run things nicely in the warehouse, but actually, you need to get product delivered into Amazon, right?

Bruno Ferreira

You do. And just to penalize very quick, when I mentioned those details and criteria to submit the ASN is that this company was actually, they received the sales order from the sales. They knew it was free boxes, but then when they were requesting the ASN and labelling, they didn't take in account that they needed to tell this is box number one and contains this. So they were just printing the labels, free labels, free boxes, and of course that caused some challenges and chargebacks in the inbound team.

So, of course, and I hope people don't think this is not, this is how I envision, I include the carrier as a partner in the logistics SOPs. I am not aware of any company that is using their own logistics to deliver to Amazon, so you will always have a partnership. Amazon allows their vendors to work with preferred carriers.

In my opinion, that's the way you should go because these companies have not a partnership with Amazon, but they know all the requirements. They have access also to carp. Carp is a web interface for carriers that Amazon allows them to use and it means carrier appointment request portal. So they use this to book the delivery. They will use an ASN number that we need to give to them, and they will arrange the booking for us. They will collect and take care of the delivery.

I think it's important to consider them as our partners, to have a good communication with them, to allow them to be aware of our internal processes. What's my cut-up time? Well, my cut-up time, I receive orders on a Monday. How many days do you need to deliver to Spain from the UK? I need five days and then my cut up time needs to be 2:00 PM on a Monday. Can we do it? So this, this visibility and communication with the carrier, it's very important too.

One of the things I noticed sometimes with companies that I help is that they think that the carrier, the preferred carrier list is a general list and sometimes it's not that simple. Different countries can have different preferred carriers. So if you are using a carrier in the UK and it's a bit more expensive, you would like to use your usual carrier to Europe, maybe that will be allowed and it's a preferred one to Germany. So maybe you can consider. So sit with your logistics team and discuss all of these points to include. It's very important in my opinion.

Paul Sonneveld

On the topic of preferred carriers, Bruno, what are the benefits of using a preferred carrier in a particular country?

Bruno Ferreira

Well, part of the key reasons to use a preferred carrier is immediately their experience delivering to Amazon. They are used to it. They know how the fulfillment centers work. They have specific slots of inbound. You see this happening in the big carriers, the big names. They have specific time slots. Some names, some big carriers will have allocated every Wednesday from 6:00 AM to 2:00 PM, it's just for them.

It's a great advantage because they can prepare and help us to prepare too. Because then we will know in this day, if they collect from me before 2:00 PM, I am sure they will deliver it on Friday because they are a preferred carrier. They have dedicated slots, and I can count on that.

Another advantage for the supplier, for the vendor is that you will be engaging in fixed costs. You can since they have these specific slots, they will be able to give you probably a fixed cost for it because they will know which fulfillment centers they will deliver. They can give you a fixed rate on a small parcel, on a pallet, on a full truckload. They can help with that. So, these are the main advantages of that.

Paul Sonneveld

Yep. Makes sense. But that could be different between countries is what you're saying. There is no such thing as, having a global partner that will cover all countries in Europe and North America, for example.

Bruno Ferreira

You can Paul. You see that the big names of distribution are across Europe and also in the UK. Also in the States, we know the names. But sometimes what it might cause is that you might not have better ratings, if you're delivering to Germany with them, maybe. But a carrier that is not available here in the UK might be available there to Germany. So maybe I can consider it and use them because they are not preferred in the UK but they are preferred in Germany as an example.

Paul Sonneveld

Yep, yep. And when it comes to delivering goods into Amazon's warehouse, who's responsible for making the booking? Getting the booking slot, at the warehouse. Is that the carrier or the vendor?

Bruno Ferreira

It's the carrier, Paul. So, the carrier, as soon as the warehouse team processes the dispatch, pick and pack labelling, it's ready to collection. It communicates usually, and these days, a lot of companies and very correctly are using EDI for the transmission. They will give them the ASN and the carrier will have access being a preferred carrier will have access to CARP.

So CARP is the web interface that Amazon gives them to book the delivery slot. With that ASN number, they will go to that system. Amazon will know as soon as they insert the ASN, they will know the delivery window, what's the latest, the delivery date, so the carrier will know, will have to deliver to that day.

Sometimes it happens in peak seasons and we all people that have experienced it happening. Sometimes I have to, the latest is the 14th and Amazon told me the 22nd. But usually, Amazon knows about that. And if carp gives the latest date after the delivery window, they will not charge you back.

But if they do, that's how it becomes important to have these bespoke SOPs and to include the carrier in them because it's important, the communication with them to be able to trace back in our own SOPs and to understand what happened. Okay? I received the chargeback. This was to the 14th. They delivered on the 22nd. We contact the carrier.

The carrier will immediately notice, okay, it was the 14th, but Carp gave us this date. And then we can open a dispute and tell Amazon, look, it was the 14th, but Carp gave our carrier partner the 22nd. And sometimes it takes some a bit of our time. It requires some dedication in some cases, but Amazon will understand and will repay for those chargebacks. But the carrier is the responsible for the booking to the delivery.

Paul Sonneveld

Yeah. As you work with vendors, and let's assume that most of them are using Amazon preferred carriers, who are professional, who do this day in, day out, and therefore, you can expect them to a reasonable job. When it comes to SOPs, I mean, where do you still feel, or where do you see things falling in between the cracks? Where do you see the broadest kind set of opportunities between the vendor, the carrier, and Amazon to three-party relationship. When things fall through the cracks, Where does that happen?

Bruno Ferreira

Well, it usually happens, Paul, if there's anything that happens that’s outside the SOP. Think about an example if there's any accident, a flat tire in the truck and everything got arranged for the delivery. So the warehouse team prepared the shipment, the carrier collected. It arranged the delivery through carp, but then something happened. So, the delivery was for the 14th, and on the 14th the truck was going to the fulfillment center, and something happened.

What might cause some challenges if you don't have that visibility on the process and if you don't have that communication, something Amazon has as an example, specific chargebacks there. It comes to my mind, a chargeback that Amazon has for no show. A no show chargeback means that you accepted the PO process that your warehouse team prepared everything, the carrier collected, arranged the booking through carp, but then it didn't show that's a fixed amount chargeback. That sometimes it's like, I call it sometimes as a ghost chargeback because people are not very aware of it, and it's a fixed one.

In case of Europe, it's 290 euros. Just think that if you are dispatching a small parcel of two boxes, an invoice value of 500 pounds, You didn't deliver, so you are not going to invoice and Amazon is going to charge you about 290 Euros. And the only reason they will do that, it's because the carrier actually booked the slot to deliver. And this no-show chargeback only happens in this situation.

So this is one of the examples that something might go wrong even with strong bespoke SOPs. What's important here is that visibility and traceability communication. We need to have a strong partnership with the carrier.

We need to know on time that something happened and I'm not going to deliver. And then the sales contact will have the tools through vendor central web interface. You will have the knowledge and the training what to do. Just go, there's a part on Amazon vendor that you can make the teams in the fulfillment center where this happened.

I remember an example that once we dispatch a big shipment to Amazon and the truck got on fire on M3 and that was a huge challenge for us. And Amazon helped us. They actually, allowed us to dispatch that order again. They didn't give us a new window, but they waived the chargeback.

So, this happened because the communication with the carrier was very quick. The carrier immediately communicated to us at 4:00 AM we have an email, this happened, and we won't be able to make the delivery. As the sales manager at the time, it allowed me to contact Amazon.

Guys, this happened. What can we do? Can I still dispatch this? And I can have this there in this date, but it'll be outside the delivery window. Amazon engaged with us. They helped us. I remember as a funny, funny part of the story, I remember that Amazon required me proof that the truck was on fire, so I sent them the link of the newspaper image.

At the time that they could see the truck on fire and Amazon will be there. But even with these SOPs Paul, they will always require for you to check them. If something consistently goes wrong, that's when you need to see it and reevaluate the SOPs, because if you get one challenge next this week, another one next week, then you need to evaluate.

I always advise the companies that I work with that keep an open mind, this is what we're starting with, but you have individual people in the warehouse. Let's give them some time. And if something is not working, let's sit with them again. Let's try to help them to understand better what they are doing or what can we change to make it easier or what is not working for you guys?

Because sometimes, and that's, that's also very important. Sometimes we sit with people that we learn them. Because their reality, actually in the pick and pack process is different from our experience and what we were envisioning for them. So this is all very important.

Paul Sonneveld

Maintaining some flexibility and adjusting as you go is absolutely critical. There's no black and white. Great. Let me pause there. We've got a couple of questions, coming in and I'd love to move into a little bit of audience Q and A. We are running pretty short on time, but keen to, get a few questions in, if you are, if you still have a few minutes, Bruno.

Bruno Ferreira

Yeah.

Paul Sonneveld

I'd love to just kick us off. One question here, was actually around the PICs program. I've come across 4 in Europe. It comes from Emil. Thank you Emil, for asking the question. Are you able to just elaborate a little bit more on the PICS program, what it means particularly, and how does it operate in Europe?

Bruno Ferreira

Okay. So PICS program Paul. It can be a great way to engage with Amazon. So Peaks program, very quick as an overview, it'll allow you to deliver to a specific country, to a selective one or two fulfillment centers instead of 10, 12 fulfillment centers.

What's that mean? You will always have a lot of fulfillment centers to deliver and you are delivering to this fulfillment center this week, to that one, this week, to a different one next week. Amazon algorithm spreads the stock to the fulfillment centers according to demand and they try to do a good job on it, and sometimes they do. But you can engage with PICS.

So, PICS will allow you to deliver to one fulfillment center or two, and then Amazon internally will distribute that stock to different fulfillment centers. It has a cost. It needs to be negotiated with your vendor manager. It'll depend on the goods, the category, but it can be a good way to control costs, to reduce your logistics costs. And in the case of what we're talking about, the bespoke SOPs, it'll not change any detail.

Because if you think about that, you'll still be delivering. But instead of delivering to 10 or 12, you're delivering to one or two. So the SOPs will be ready for that two. But the consideration here is the impact on your fixed costs of transport, Can they be improved because you are delivering to one or two fulfillment centers, but you are paying an extra to Amazon for them to distribute internally.

Paul Sonneveld

Thank you. We have a question here from, Susanna. It's a long one, so let me just read it out. “In Germany, we often get issues with loading bans as we ship LTL with a preferred carrier however they don't get enough slots at the AMZ FCs for their trucks with mixed POs and then they their warehouse gets too full and they can't take our POs. Any recommendations on these issues?” Feel free to just read through it a little bit more, it’s a long question.

Bruno Ferreira

Yeah. Well, in this situation, Paul, what I would advise is to get in touch If you have a vendor manager to expose the situation, I would advise to do an audit on the past six one year that this is happening, and show them through the data that you have access and show them, look, this consistently happens in this fulfillment centers.

What can we do to improve? I am here as your partner. Because are Amazon partners. This is a B2B business. We are their partners, so they also need to help us with this kind of challenge. I would advise to go to the vendor manager if you don't have a vendor manager build a strong case and open a support case ID. And show them what's happening here. What can be the cause of this?

I'm thinking about an example. A few years ago, I was working with a company and I started to receive a lot of chargebacks from France and there was something there of course, that three, four weeks into it, there was something there. So I went into a, a deep dive into the data of the performance reporting and I noticed that the chargebacks were coming always from the same fulfillment center. So I went to my vendor manager, I showed him the data and we just stopped delivering to that fulfillment center and everything improved after that.

So I would advise to, on one side, if you have a vendor manager to discuss this with them. If not to get that reporting on those, fulfillment centers. Open a support case ID. Be patient, insist and they will help you to sort it. But from my experience, the way you speak to the support team and how you expose the data to them, it's very important to success. So I hope I can help with this. If not, Susanna, you can just direct message me and then we can look into that in more detail.

Paul Sonneveld

Yeah. Thank you, Susanna. Difficult and tricky question. Let me finish with a last question for myself, which is just around, unhealthy inventory and overstocks. When your inventory inside Amazon's warehouse just gets too much, or at least in the eyes of Amazon, how do you work through a situation like that with your Amazon vendor manager where there's pressure on you to take some of the stock back?

Bruno Ferreira

Yeah. Well, first of all, I don't agree with an overstock allowance from Amazon and it's always a tricky point in the negotiation. Of course, sometimes we need to commit with Amazon, it requires to meet in the house sometimes. What I advise my company is always is to keep in mind one thing. It's not wrong to say no to Amazon. This is usually how I start my conversations. We are going to learn now to say no to Amazon.

And regarding the overstock returns, it's sometimes a pain, and you need to think that if you agree with an overstock return, you are actually giving Amazon the power to return wherever stock they want. So, we're not working in a consignment model, are we? So how can we play these very requirements from Amazon for the pick and packing and all of that. How can we use that in our favor?

Think about this. Every supplier for vendor central has at least one type of returns, DOA. It means damage on arrival. It means that Amazon inbound team will actually check the packaging, the profit, and if there's a dent, if there's anything that allows them to consider not mean condition, they will return that stock to you. So when you have an overstock agreement, what I advise my companies is let's include that return process in the SOPs. And as you can see, I put that in the carrier because it's actually after the delivery and the carrier will bring it back.

A few details about this Paul are Amazon, if you're not aware, will input the handling costs of that return on you, and you will also pay the transport of the Overstock. Okay? So, if you are not aware of that, check your terms and conditions, and you'll see that Amazon will input those charges to you.

How to deal with this? How can we use the rules of Amazon in our favor too? Well, If Amazon doesn't receive damage on arrival stock, then we are not to receive them too. It means that if you have a bespoke SOP, like the ones that I help the companies with, let's check the boxes. Amazon returned them to us. It's overstock. I cannot accept this because it has a dent, so you need to take it back.

From my experience, Amazon. Majority of times will agree, take it back. I've even have situations where companies were able to recover the transport costs of the overstock return and Amazon paid the transport costs sending them back to them.

Paul Sonneveld

That's very interesting. There's a common thread through a lot of things that you were saying, Bruno, which is all about getting an accurate picture, getting the data, creating transparency, and just sort of holding up the mirror back to Amazon.

Bruno Ferreira

In this particular situation, I always tell companies you need to say no. So if Amazon just think the logic is, if Amazon is not accepting this because they say it's damage, they say they cannot sell it. Why should you accept? You cannot sell it too. Because it went to Amazon Fulfillment Center.

Sometimes I've seen situations where as, as soon as it gets processed by the inbound team, Amazon sometimes places, ASN label on top of the EAN barcode on the product. You don't even need to have a dent on the box. If you receive the box that is covering the EAN of the product with an ASN label from Amazon that they apply internally.

If you are removing that sticker, you are damaging the EAN. You cannot sell that to a client. And I've had success on returning back to Amazon saying, sorry, you apply the label on the EAN code. I am not able to resell this to any other of my clients. And Amazon, from my experience, understands this. So this is a good way on the overstock to play the rules as they are, because terms and conditions, if you notice, are both ways. So if Amazon doesn't accept, I hope people understand this. If Amazon doesn't accept DOA, we shouldn't accept DOA too.

Paul Sonneveld

That is a great place to finish. Some wise words there, Bruno. We are out of time. So we're going to have to wrap up. First of all, let me thank you again for just coming on the show and just sharing, just a tiny fraction of all of your experiences, all of your work. Probably a lot of painful learnings over the years.

Bruno Ferreira

Yes.

Paul Sonneveld

You'd probably make it sound easy, but I'm sure there was some blood, sweat and, and tears involved. So thank you for your generosity. There might be viewers or listeners to our podcast later who might be interested in getting in touch with you, Bruno, and, exploring something further. What is the best way for them to do that?

Bruno Ferreira

Well, the best way, Paul, I just placed my email address. On the screen it's bruno@bluedotecommerce.com. Yep. Just get in touch. I would love to hear about the challenges you are currently going. For me, it's my passion. It's always learning. I love to get a new challenge and to advise companies and it's always great when I see, as we're talking about logistics, it's always great when I see a warehouse manager that the conversation didn't start that friendly.

And then years later, we're still good friends and I still get some texts on my birthday because it was hard to start. But then they understood and they saw the value on that.

Paul Sonneveld

Yeah. Fantastic. All right, well thank you so much Bruno. You know, I was going to say goodbye. We, we will have another session coming up talking about finance SOPs for those accountants out there. Make sure you keep an eye out for that. We'll probably do that in early April or so. But thank you so much for being on the show and till next time.

Bruno Ferreira

Thank you Paul.

Paul Sonneveld

All right, everyone. Well, that is a wrap for this episode of Marketplace Masters. There was a question earlier about where to find part one. The best place or the easiest place to find is just a head of merchantspring.io. That's merchantspring one word dot io. Go to our resources section and have a look at our on-demand videos and webinars.

You'll find episode one on there and you'll find this episode on there very, very shortly. With that, I thank you for listening and I look forward to the next episode. Thank you.

Add a Comment