Inside Amazon Direct Fulfillment: What High-Performing Vendors Know (That You Don’t)

Overview

Amazon’s Direct Fulfillment program for first-party (1P) vendors is a powerful but often misunderstood model in the e-commerce arsenal. In Direct Fulfillment (also known as Amazon drop-ship), a vendor ships products directly to the end customer on Amazon’s behalf, instead of shipping bulk inventory to Amazon’s warehouses as in the traditional Vendor Central model. This approach can drive operational efficiency, reduce inventory risk, and boost profitability when executed correctly. Below, we break down what Amazon Direct Fulfillment entails, its key benefits and drawbacks, and how vendors can successfully leverage it in line with best practices and profitability goals.

What is Amazon Direct Fulfillment?

In Amazon’s Vendor Central ecosystem, Direct Fulfillment (DF) is essentially a retail drop-shipping program. Instead of Amazon ordering large quantities via purchase orders and then fulfilling customer orders from its warehouses, the vendor accepts customer orders and ships items directly to the consumer – but as an Amazon order. From the customer’s perspective, the product still appears as “Sold by Amazon” and usually wins the Buy Box, but the fulfillment is handled by the vendor behind the scenes. The main difference from the standard 1P model is that with Direct Fulfillment, the vendor doesn’t need to send stock to Amazon’s fulfillment centers in advance; every unit is shipped on-demand when a customer purchase is made.

Because Amazon is effectively outsourcing the warehousing and dispatch to the supplier in DF, the program is invite-only. Vendors must be invited by Amazon to participate (though you can request access via your Amazon vendor manager or support if you meet the criteria). Once invited, setting up Direct Fulfillment is straightforward: you configure a “direct fulfillment warehouse” in Vendor Central (with your ship-from address and pickup times), integrate or use Amazon’s provided shipping labels (via Vendor Central or EDI/API), and then load your product catalog and inventory availability for DF orders. Amazon will then start routing orders to you for direct shipment whenever those items are ordered. Inventory updates in near real-time (within minutes), so you can adjust stock levels frequently to reflect what you can fulfill.

Key Benefits of Direct Fulfillment

For vendors capable of meeting its demands, Amazon Direct Fulfillment offers several compelling benefits:

- Expanded Catalog Coverage: All of your ASINs can be live and sellable on Amazon, even items Amazon might not normally stock. You aren’t limited by what Amazon chooses to purchase—list your full catalog and new products without waiting for Amazon purchase orders. This means new sales opportunities through an expanded offering of products that can appear on Amazon’s marketplace from day one. It’s an especially great way to launch new products: you can make a new ASIN immediately live on Amazon via DF, rather than waiting for Amazon to accept a bulk order or initiate a test order (like the Born to Run program).

- “Always In-Stock” Backup: Amazon often pitches DF as a way to avoid stockouts. If your regular in-stock (warehouse) inventory sells out or faces inbound delays, Amazon can fall back on vendor-drop-shipping so you don’t lose sales velocity due to out-of-stock issues. In other words, Direct Fulfillment can serve as an insurance policy for stock availability, keeping products available to buy on Amazon even when their fulfillment centers run dry.

- No Purchase Order Lag: In the traditional Vendor model, you rely on Amazon to send POs and forecast demand. With Direct Fulfillment, you don’t need to wait for Amazon’s purchase orders at all. As long as you have inventory on hand, you can make it available for sale. This greatly reduces the lead time for new listings and prevents missed opportunities—vendors can introduce products immediately and test demand directly rather than convincing Amazon retail to stock up.

- Amazon-Funded Freight: Amazon covers the cost of shipping to the end customer for DF orders. In practice, this means significant freight savings for the vendor, since you’re not paying to ship cases or pallets to Amazon’s distribution centers (and Amazon pays the last-mile delivery to the shopper). Essentially, the vendor acts as a drop-ship warehouse for Amazon, and in return Amazon foots the bill for delivery to the customer. This can particularly benefit heavy or bulky items with high shipping costs – Amazon will pay those costs when you fulfill via DF.

- Fewer Chargebacks & Compliance Fines: Direct Fulfillment comes with fewer operational penalties compared to traditional 1P. For example, you won’t incur chargebacks for things like prep mistakes or late inbound shipments, since you’re not shipping into Amazon’s network. There are far fewer compliance fine opportunities on the DF side. In fact, Amazon’s metrics for DF are largely centered on fulfillment performance (e.g. cancellation rate, ship timeliness) rather than a laundry list of chargeback codes. Aside from one major exception (cancelling a customer order, discussed later), vendors find DF a lighter touch in terms of fines and chargebacks.

- Broader Availability = More Sales: By leveraging DF, many brands see overall sales growth. All else equal, having more products live, never running out of stock, and offering a wider assortment can drive additional revenue. For example, one agency noted that 95% of their Vendor Central clients in the Midwest participate in Direct Fulfillment, and this strategy has “resulted in a lot of increased business for everyone” – it’s even their preferred method to launch new products on Amazon. In short, when done well, DF can be a growth engine for vendors to maximize Amazon marketplace presence.

Challenges and When It’s Not a Fit

Despite its advantages, Direct Fulfillment is not right for every vendor or every product. There are important challenges and considerations to weigh:

- Operational Demands: Taking on DF means you, the vendor, handle the pick-pack-and-ship process for each customer order – a role Amazon would normally play. If your company is not operationally efficient at fulfilling individual orders, DF can become problematic. You must be able to process small orders (even single units or eaches) quickly and consistently. Vendors who lack the warehouse facilities, staff, or systems for direct-to-consumer fulfillment may struggle. In fact, many manufacturers choose to partner with a third-party logistics (3PL) provider to handle drop-ship orders if they can’t do it in-house. If you cannot reliably pick, pack, and ship daily orders at the case or unit level, Direct Fulfillment might not be a good program for you (at least until you shore up your operations).

- Packaging and Labeling Requirements: While simpler than Amazon’s vendor freight compliance, DF still has specific requirements (e.g. using Amazon-provided shipping labels, packing slips, and respecting customer privacy data). Some manufacturers struggle with the labeling or packaging rules – for instance, ensuring no promotional materials are included and handling Amazon’s carrier labels properly. Because Amazon provides customer information for shipping, you also need processes to safeguard that data and meet any privacy standards Amazon sets. These requirements are not overly numerous, but failing to follow Amazon’s DF packing/shipping guidelines can lead to problems, so vendors must be prepared to handle them.

- Longer Lead Times for Customers: Amazon Prime has trained customers to expect ultra-fast delivery (often same- or next-day). With Direct Fulfillment, shipments originate from the vendor’s facility, which might not be as widespread or efficient as Amazon’s network. Customer ship times on DF orders are typically a bit longer, often a few days, depending on where your warehouse is and how quickly you dispatch. Amazon will display a longer delivery promise (e.g. “2-5 days”) for DF items versus the nearly instant Prime delivery for FBA/warehouse items. While this isn’t a deal-breaker, it means DF items may convert a bit lower if competing against Prime offers, and you must consistently meet your stated lead times to keep that delivery promise from slipping further.

- Dual Systems for Hybrid Vendors: If you use a mix of in-stock (FBA/warehouse) and Direct Fulfillment for the same products, be aware it adds complexity. Amazon treats the DF warehouse as a separate vendor code – effectively a second account for the same vendor – which means you might need to maintain two sets of data for an item. For example, pricing or cost changes have to be updated in two places (the in-stock vendor code and the DF vendor code) because Amazon allows you to set different costs for DF vs. warehouse. This can complicate negotiations and adjustments, since managing a hybrid model requires diligence to keep both “accounts” in sync. It’s manageable, but vendors should be prepared for a bit of duplicated effort if running products in both fulfillment modes.

- High Cost or Inventory Suppression: Amazon’s system will flag or suppress DF listings under certain conditions, which can catch vendors off guard. In Vendor Central’s DF inventory screen, you might see item suppressions with reasons like “high cost” or “other reason”. A high-cost suppression indicates Amazon believes the item’s cost (and thus retail price) is too high to be competitive, so they temporarily stop showing it. Other suppressions may occur if Amazon’s own warehouse has plenty of stock of that item, effectively telling you not to load more DF inventory. These automations mean that even if you want to sell an item via DF, Amazon might throttle its availability. Vendors need to monitor their DF inventory statuses and work with Amazon to resolve any suppressions (though sometimes the only remedy is time or adjustments to cost).

- It’s All on You: Perhaps the biggest “con” is simply that Direct Fulfillment shifts much of the fulfillment burden and risk onto the vendor. Amazon loves DF because it reduces their warehouse space, inventory risk, and labor costs – but that means you must absorb those responsibilities. You’ll be managing more processes (order fulfillment, warehousing, shipping issues) on a day-to-day basis. If something goes wrong – a late shipment, an incorrect item sent, etc. – it’s on your operations. In a worst-case scenario, consistent failures (like canceling orders you cannot fulfill) can lead Amazon to suspend your DF capabilities. Thus, a vendor should only opt into Direct Fulfillment if they are confident in meeting Amazon’s standards consistently. As Dan Nowak put it succinctly, if you can’t pick, pack, and ship efficiently at the unit level, you probably shouldn’t participate.

Getting Started with Direct Fulfillment

If the benefits sound enticing and the challenges seem manageable, how do you actually begin with Direct Fulfillment? Here are the key steps to get started:

- Obtain an Invitation: Direct Fulfillment currently requires Amazon’s invitation for your Vendor Central account. Vendors who would benefit (or those with strong Amazon Vendor performance) can often request access. Reach out to your Amazon Vendor Manager or Vendor Support and express interest in joining the Direct Fulfillment program. Amazon has an incentive to enroll capable vendors (it offloads their warehouse load), so they are usually receptive if you meet the operational criteria. It may take some time, but getting that invite is the first gate to pass.

- Configure Your DF Warehouse: Once approved, Amazon will enable a Direct Fulfillment warehouse on your account. In Vendor Central, you’ll set up details for this DF warehouse – such as the ship-from address, pickup hours, and carrier information. Amazon typically provides you with UPS/FedEx account numbers or shipping labels to use for outbound orders, or you can integrate via EDI/API to pull Amazon’s labels into your system. Essentially, you decide whether you’ll print labels and fulfill orders directly through the Vendor Central portal or integrate the process with your own warehouse management system. At this stage, ensure your warehouse team is trained on the DF process (receiving orders, printing Amazon labels, packing with Amazon-branded documentation, etc.).

- List Products and Inventory: With the warehouse configured, you can now enable products for Direct Fulfillment and load inventory quantities. You choose which SKUs/ASINs to make available via DF (it could be your entire catalogue or a subset). For each item, you’ll provide an available-to-sell quantity that Amazon can tap into. One advantage is that you can list items in DF that Amazon might not have ordered for regular in-stock, thereby immediately expanding your storefront. Inventory levels can be updated frequently – Amazon’s system can refresh the available inventory as often as every 5 minutes. A best practice is to only list inventory you are confident you can fulfill; remember, listing high inventory and then failing to ship (cancelling orders) will incur penalties. Start with conservative stock numbers if needed and adjust as you get a handle on order volume.

- Plan for Demand Generation: Simply listing products via DF doesn’t guarantee sales. Especially for new products or SKUs that had no prior Amazon sales history, they will be essentially invisible in Amazon search results initially. Be prepared to drive demand through marketing, just as you would when launching a new product. This means leveraging Amazon Advertising (AMS/PPC) to get your DF listings in front of customers. According to the experts, you’ll likely need to invest extra in advertising at launch – bidding for sponsored placements – to generate the first sales and momentum. Over time, as the product gains organic sales velocity and reviews, you can taper down ad spend, but upfront promotion is key to kickstart sales for a DF item.

- Optimise Product Content: In tandem with advertising, make sure your product detail pages are fully optimised for conversion. Direct Fulfillment items should not be treated differently than regular Amazon listings when it comes to content quality. Use high-resolution images, compelling titles and bullet points, A+ Content, and ensure the pricing is attractive. Since DF allows many more items to be listed, don’t neglect content on any newly-listed ASINs. Strong product pages will improve your conversion rates and advertising efficiency, helping your DF items succeed. As Steven Glass emphasised, focus on your product detail page – make it as meaningful and powerful as any in-stock product’s page.

- Leverage Hybrid Fulfillment Wisely: If you have the option to sell an item both via in-stock (Amazon warehouse) and DF, develop a strategy for it. You might, for example, use DF to test new products or carry low-volume SKUs, while reserving Amazon warehouse fulfillment for your high-volume “core” items. Amazon will generally default to its own stock first (since they’ve invested in that inventory), but you can influence this. One tactic is that if you prefer Amazon not to stock an item, simply don’t accept the purchase order for it – there’s no chargeback for politely declining POs. Amazon will then rely on DF for that SKU. Conversely, if an item is better fulfilled by Amazon (small, fast-moving units), you might keep it out of your DF catalog or set low DF inventory so Amazon continues to reorder it for in-stock. The key is you have flexibility to choose which products live in which fulfillment channel. Use that control to maximise both sales and efficiency for each item.

Operational Best Practices for Direct Fulfillment

Once you’re up and running with Direct Fulfillment, success largely comes down to operational excellence. Here are some best practices and tips to ensure smooth operations and avoid common pitfalls:

- Align Your Team and Processes: Treat DF as a new capability that requires cross-functional coordination. Make sure all team members – from warehouse staff to customer service and account managers – understand how the program works and what their responsibilities are. It’s wise to invest time upfront in training and documentation for the DF process. If everyone internally is on the same page, you’ll prevent mistakes. Internal alignment includes setting expectations around lead times, order volumes, and the importance of meeting Amazon’s metrics. Many issues can be avoided by simply ensuring your team is well-prepared before volumes scale up.

- Master Inventory Management: Accurate inventory tracking is absolutely critical in DF. Keep your available-to-promise inventory in Vendor Central updated in real time or on a frequent sync. Remember, listing an item as “in stock” means Amazon might sell it immediately – you must be able to ship it. Running out of stock without updating the system leads directly to cancelled orders (and penalties). A good practice is to integrate your inventory system with Amazon or set up automated updates multiple times a day. Also consider using safety stock buffers: for example, if you have 100 units on hand, you might only list 95 in Amazon to account for any discrepancies or other channel sales. This reduces the chance of an Amazon order that you can’t fulfill.

- Optimise Lead Times via Virtual Warehouses: Amazon’s DF allows you to create multiple virtual warehouses to represent different shipping lead times or locations. Take advantage of this to manage diverse product categories. For instance, you might set up one DF warehouse code for products that ship out same-day or next-day, and another for products that need longer lead times (e.g. made-to-order items or bulky goods). By grouping products by similar fulfillment speed, you ensure Amazon’s displayed delivery promise is accurate for each item. This prevents situations where a custom-made product accidentally shows “Available to ship tomorrow.” It also improves customer satisfaction by setting proper expectations. Adjust your lead times if you notice any slippage – Amazon will automatically extend the promised window if your actual fulfillment lags, which can hurt conversion. Proactively managing lead times via these virtual warehouse groupings helps keep your DF performance strong.

- Avoid Cancellations at All Costs: In Direct Fulfillment, the cardinal sin is cancelling a customer order after you’ve accepted it. Amazon heavily frowns on this. In fact, cancellation is one of the only infractions that carries a direct financial fine in DF. If you cancel too many orders, Amazon can even suspend your DF privileges and ask for a plan of action to fix the issues. To avoid cancellations, never let your Amazon DF inventory get ahead of what you can actually ship. It’s better to list a smaller quantity and sell out (you can always add more later) than to over-promise and end up cancelling. Also, if you encounter an inventory discrepancy or a sudden stockout, communicate quickly – in some cases, it may be better to request Amazon cancel an ASIN’s availability before orders come in, rather than cancel individual orders after the fact. The bottom line: only accept orders you can fulfill on time. This also ties back to inventory management and team alignment – accuracy and caution here preserve your DF reputation.

- Monitor Performance Metrics: Amazon will track your DF performance on metrics like on-time shipment rate, fill rate (cancellation rate), and late shipment rate. While Amazon doesn’t levy dozens of chargeback fees in DF, they do effectively penalise you by lengthening your lead times if you perform poorly. For example, if you consistently ship orders out late, Amazon will automatically adjust the handling time it shows customers (e.g. increasing from 2 days to 5-7 days), which can reduce your conversion and sales. So, stay on top of those metrics. Aim to ship every order within the expected window and keep cancellations near zero. If metrics start slipping, identify the root cause (warehouse bottleneck? inventory miscounts? carrier pickup issues?) and correct it quickly. The absence of heavy fines is forgiving, but poor performance will still hurt your business over time.

- Control Costs and Efficiency: Because you are effectively running a fulfillment operation for Amazon orders, watch your internal costs to ensure DF remains profitable. Track the labor, packaging, and any storage costs associated with these orders. You might find that certain products aren’t worth doing via DF if they are too costly to ship or handle. Conversely, you might discover efficiencies at scale. Some vendors, after refining their DF process, choose to ship exclusively via Direct Fulfillment for certain lines because they’ve become very efficient at it (and avoid Amazon warehouse fees). Periodically review if your DF assortment is yielding healthy profit margins and adjust as needed – e.g. by setting higher costs to Amazon for very expensive-to-ship items, or by moving some items back to in-stock if DF costs are too high.

- Consider Partner Support: If all of this feels overwhelming, remember that you don’t have to tackle it alone. Many vendors work with specialised agencies or logistics partners (like the Resource Group Midwest team featured in our discussion) that can manage or advise on Direct Fulfillment operations. These partners can help set up EDI integrations, optimise processes, or even handle the day-to-day DF orders on your behalf. While it’s an extra cost, outsourcing the complexity can pay off if it lets you offer DF capabilities without diverting too many internal resources. The key is to ensure whoever manages your DF (whether internal or external) is deeply familiar with Amazon’s requirements and best practices, so you maintain high performance.

Profitability Considerations in Direct Fulfillment

One of the most important questions for any vendor is: How will Direct Fulfillment affect my bottom line? The answer depends on your operations, but in many cases, Direct Fulfillment can be more profitable than traditional wholesale – if executed well. Here’s why:

- Lower Vendor Costs: Many of the extra costs vendors incur with the regular vendor model are minimised or eliminated in DF. You won’t be paying for freight to Amazon’s warehouses, and you avoid a host of chargeback fines (like missed delivery windows, routing errors, etc.). Those savings can be significant, effectively boosting your margins per unit. Additionally, having more items for sale (wider assortment) can increase your top-line revenue. Dan Nowak observed that for most of their clients, DF turned out to be a more profitable model overall – as long as they could handle the operations – because of fewer compliance issues and no freight expense to Amazon.

- Inventory Risk and Cash Flow: With DF, you are not forced to ship large quantities to Amazon that might sit unsold. You keep inventory until it actually sells to an end customer. This reduces inventory risk – you’re not tying up capital in inventory sitting at Amazon, which might get returned or disposed of if it doesn’t move. You can also more nimbly adjust to demand (since you retain stock and control how much to list). In essence, DF can lead to a leaner, just-in-time approach for some products, improving inventory turnover and cash flow. And if a product doesn’t sell, you haven’t incurred outbound freight or Amazon storage fees on a failed gamble.

- The Catch – Internal Fulfillment Costs: The flip side is that Amazon’s “free” warehousing and fulfillment is gone – you assume those fulfillment duties and costs. Labor, packaging, warehousing, and shipping preparation costs fall on the vendor, so you must account for these when evaluating profitability. If your operation is efficient (or if you have excess warehouse capacity already), you might handle this at relatively low incremental cost, thus netting a gain. But if you need to invest heavily in new staff, space, or systems to do DF, those costs can eat into or even outweigh the savings. The key is scale and efficiency: the more orders you fulfill smoothly with a given setup, the lower your per-unit cost will be. It’s wise to calculate your per-order fulfillment cost and compare it to what Amazon’s terms are with traditional vendor orders to see how the economics truly net out.

- Outsourcing vs. In-House: Some vendors may find it unprofitable to build a direct fulfillment capability internally (especially smaller vendors), but they can partner with a 3PL or drop-ship specialist. This adds a fee, but if that partner is highly efficient, it might still be profitable overall. Other larger vendors might invest in automation in their own warehouses to drive DF costs down. The decision comes down to volume and capability. For those who can execute well internally, DF often yields higher profit per unit; those who can’t may see profits erode unless they outsource or stick to the regular model.

- Product Selection for Profit: Not every product will be equally profitable under DF. Large, bulky products are actually great candidates, because Amazon’s model is ill-suited to them (they take up too much space and are costly for Amazon to ship). Amazon often doesn’t like to stock these in their fulfillment centers, so DF is a way to sell big items without those storage fees – and Amazon foots the heavy freight bill to the customer. This can make formerly margin-thin items more viable online. Made-to-order or customised items are another good fit – items that you produce on demand can’t sit in an Amazon warehouse for immediate shipment, but with slightly longer lead times via DF, you can still offer them for sale. On the other hand, very small, fast-moving items might be less profitable via DF if your per-order labor and shipping costs exceed Amazon’s efficiency at scale. Many vendors adopt a hybrid approach: use DF for the items that are expensive for Amazon to hold or that need your special handling, and keep the rest in Amazon’s regular in-stock program. This way you maximise profitability for each segment.

In summary, Direct Fulfillment profitability comes down to a trade-off between savings (freight, fines, faster listing of new products) and assumed costs (your own fulfillment expenses). Vendors who are already adept at direct-to-consumer shipping often find DF quite profitable. As one expert put it, most clients see it as “a more profitable model, if you can operationally do it”. Just go in with eyes open about what it takes on the operations side, and make sure to scale appropriately.

Conclusion

Amazon Direct Fulfillment can be a real game changer for vendors – unlocking broader assortment availability, greater control over stock, and potentially higher margins. It empowers brands to keep products in stock on Amazon all the time and launch new items on their own terms. However, DF is not a magic bullet for everyone. The model shifts significant responsibility to the vendor, meaning success requires top-notch operational capabilities and attention to detail. If implemented without the necessary infrastructure and commitment, it could just as easily lead to headaches or profit erosion.

The good news is that with careful planning and adherence to best practices, these pitfalls can be avoided. The experiences shared by seasoned experts make it clear that operational excellence is the linchpin – if you can maintain efficiency and reliability, Direct Fulfillment is an immensely powerful tool in your Amazon strategy. It’s about balancing the pros and cons: taking advantage of Amazon’s reach and a wider catalogue, while managing the logistics with discipline.

Looking ahead, the trend among manufacturers and vendors is toward greater adoption of drop-ship models like Direct Fulfillment. Amazon continues to encourage this to reduce its own storage burdens, and many brands are investing in the people, processes, and systems to support it. In some cases, companies are even outsourcing the complexity to experienced partners so they can reap the benefits without getting bogged down. In any case, Direct Fulfillment is likely to become even more common in the coming years as part of a modern Amazon vendor strategy.

For now, if you’re a vendor with the operational strength (or the right partners), Direct Fulfillment is well worth exploring. It can boost your sales, protect you from stockouts, and improve profitability – all while deepening your direct connection to Amazon’s customers. Just remember the mantra: do it right, or don’t do it at all. With the insights and tips above, you’ll be well on your way to making an informed decision and, if you proceed, executing Direct Fulfillment the right way for your business.

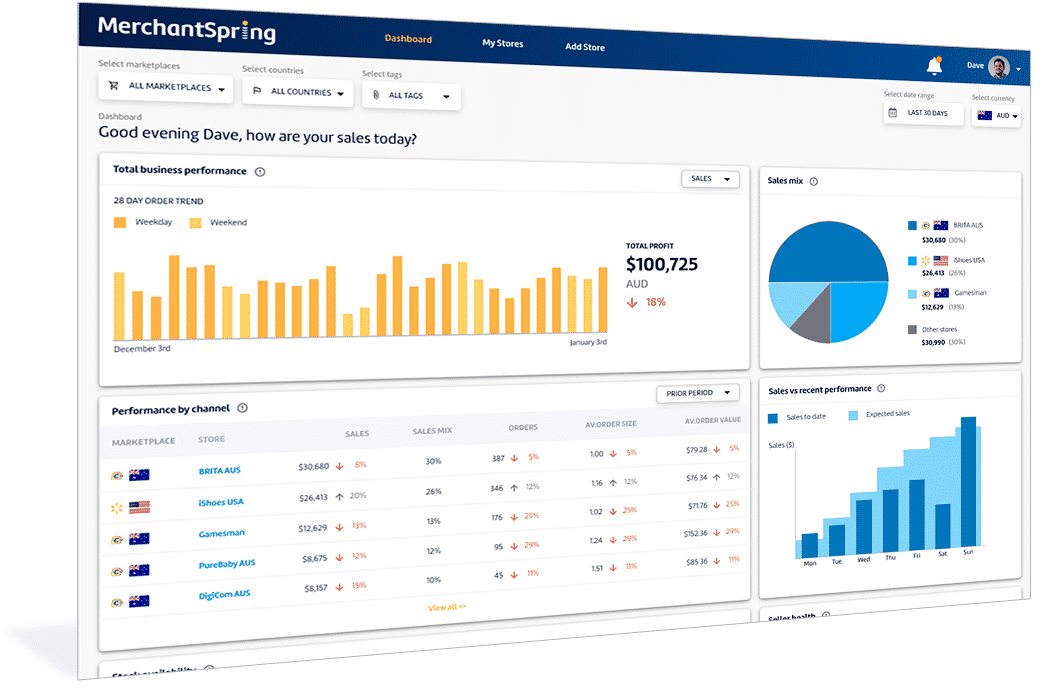

Want to see how MerchantSpring can help you manage and optimise Amazon Direct Fulfillment at scale?

👉 Book a demo to explore your opportunities.

🎥 Or, catch this episode and more insights anytime on our Marketplace Masters on-demand page.

%204-2.png)

Add a Comment