Agile Over Accurate: How Smart Vendors Stay In-Stock on Amazon 1P

Overview

Forecasting in Amazon’s first-party (1P) Vendor Central environment is critical for staying in-stock yet notoriously challenging. Unlike traditional retailers that share demand forecasts or place orders months in advance, Amazon keeps vendors guessing with its just-in-time ordering approach.

In a recent Marketplace Masters webinar titled “Mastering Forecasting and In-Stock Availability,” host Paul Sonneveld interviewed Justin McMillan (co-founder of Rebelution, a 1P-focused agency) to uncover strategies for forecasting on Amazon 1P. This guide distills their insights – from building accurate sell-through forecasts to managing Amazon’s unpredictable purchase orders – and combines them with broader best practices for Amazon vendors. The goal is to help vendors move from flying blind to forecasting with confidence in the Amazon ecosystem.

Why Amazon 1P Forecasting Is Uniquely Challenging

Forecasting demand for Amazon 1P is not as straightforward as with other retailers. Key challenges include:

- Lack of a Demand Plan: Amazon does not share a traditional demand plan or guaranteed purchase order (PO) schedule with vendors. In conventional retail, partners place POs well in advance, giving suppliers a clear forecast. Amazon, by contrast, operates on a just-in-time purchase order system – ordering stock only as needed to meet current demand. This minimizes Amazon’s inventory holding costs (avoiding overstock) but leaves vendors with little visibility.

- Opaque Ordering Algorithm: Amazon’s ordering can fluctuate for reasons beyond pure consumer demand. For example, Amazon might throttle orders if it anticipates lost Buy Box issues, sees sudden competition or traffic drops, or runs into its own warehouse capacity constraints. These factors are often invisible to the vendor, making it feel like you’re “flying blind” in trying to predict POs. Vendors often must forecast sell-out (consumer demand) while getting paid on sell-in (Amazon’s buy orders), and the two don’t always align.

- Probabilistic Amazon Forecasts: Amazon does provide some forecasting data in Vendor Central (the Retail Analytics Forecasting report), including mean and P70/P80/P90 demand forecasts. However, these are customer demand forecasts – not commitments to buy. For instance, a P80 forecast is the level of weekly demand Amazon is 80% confident will not be exceeded. Actual PO volumes may differ significantly, because Amazon’s forecast is “demand- not buying-oriented,” and it adjusts frequently based on real-time trends. Justin noted that Amazon’s P70/P80/P90 figures can swing by ~10% up or down in a short time, especially after unexpected spikes or drops in sales. At an aggregate level the forecast might look reasonable, but at the ASIN level it can be wildly off if a product’s trajectory changes suddenly.

- No Commitment to Purchase Orders: Because of this volatility, Amazon rarely commits to specific future order quantities. They won’t give hard monthly or quarterly PO forecasts to vendors. Even Amazon’s own Vendor Managers – who focus more on growth and profitability – often cannot tell a vendor exactly when or how much Amazon will order. This uncertainty forces vendors to plan for a range of scenarios rather than a single locked-in number.

Bottom line: Amazon’s 1P model prioritizes agility and efficiency for Amazon, at the expense of vendor predictability. The onus is on vendors to forecast end-customer demand as best as possible, knowing Amazon’s orders may lag or lead that demand. In this environment, a “perfect” forecast is impossible – instead, the focus must be on responsiveness and buffer planning.

Building an Accurate Sell-Out Forecast

Since Amazon won’t tell you exactly what they plan to buy, the starting point for vendors is to forecast “sell-out”, i.e. consumer demand for your products on Amazon. Justin McMillan recommends the following approach:

- Use Historical Data (12–24 Months): Begin with as much sales history as you have – ideally the past year or two of Amazon sell-through data. This establishes a baseline of natural demand and growth trends (or seasonality) for each ASIN. Look at units sold or cost of goods sold (COGS) over time to gauge average velocity.

- Layer in Key Drivers (“X Factors”): Adjust the baseline using factors that can influence demand, such as:

- Advertising and Promotions: Planned increases in Amazon Advertising spend, deals (like Prime Day lightning deals), or promotions will lift demand. Account for any scheduled campaigns.

- Seasonality: If the product is seasonal (e.g. back-to-school, holiday spikes), model those patterns using last year’s uplift as a guide.

- External Marketing or Influencers: Include any off-Amazon marketing efforts (social media campaigns, influencer features, press releases) that the brand is running. These can cause sudden surges in Amazon demand (e.g. a viral TikTok video can spike sales for a week).

- Competitive or Distribution Changes: If a competitor went out of stock or you gained new distribution (or lost other channels), adjust the demand. Also, if the brand plans to shift some Amazon 1P business to 3P or vice versa, factor that in.

- Advertising and Promotions: Planned increases in Amazon Advertising spend, deals (like Prime Day lightning deals), or promotions will lift demand. Account for any scheduled campaigns.

- Focus on Traffic and Conversion: Amazon’s ecosystem is largely driven by the amount of traffic (page views) and how well that traffic converts to sales. If you expect a jump in traffic (say, from improved search rank or ads) or a conversion rate improvement (better content, pricing, etc.), incorporate those into the forecast. For example, doubling ad spend might significantly increase page visits; a site-wide conversion average can then translate that into units sold.

- Coordinate with Internal Teams: Don’t build the Amazon forecast in isolation. Talk to the brand’s marketing and sales teams for any plans that aren’t obvious in the historical data. For instance, if the marketing team has a major PR event or a product redesign launch in six months, that insight needs to feed the forecast. Justin emphasizes that brands often hold valuable knowledge of upcoming initiatives – tap into that.

- Units and COGS as Metrics: Many vendors forecast in terms of units or COGS (cost of goods sold to Amazon). Justin’s team typically looks at the 12-month rolling COGS per ASIN as a starting point. From there, they apply expected growth rates for each product (which could be based on year-over-year trends or targets). Growth may not be uniform across the catalog; identify hero products vs. steady performers and project each appropriately. The result is a forecast of how many units (or how much COGS value) Amazon could sell to customers in the coming weeks and months, if stock is available.

By combining a data-driven base with informed assumptions, you get a sell-out forecast – essentially the demand side of the equation. This is your best estimate of true consumer need. The next challenge is translating that into Amazon’s ordering behavior (sell-in), which is where things get tricky.

Bridging Sell-Out to Purchase Orders (Sell-In)

How do you go from a customer demand forecast to predicting Amazon’s POs? There will always be a gap, but here are some tactics and considerations to bridge it:

- Understand Amazon’s Forecast Data: As mentioned, Vendor Central provides mean, P70, P80, P90 forecasts for demand. To clarify: a P80 forecast means Amazon is 80% confident weekly customer demand will be at or below that number. Higher “P” levels correspond to more conservative (higher) demand estimates. These can be used for risk planning – e.g. P90 is a high-side scenario (only 10% chance demand exceeds it). However, remember these are not commitments to buy inventory. Amazon’s actual PO may undershoot or overshoot these if its algorithm decides to.

- Track the Variance: If possible, compare your own sell-out forecast to Amazon’s P70/P80. Don’t be surprised to find differences. As Justin noted, Amazon’s forecast might change week to week and sometimes be off by double-digit percentages. For example, an unexpected sales spike from an external event can quickly raise Amazon’s demand forecast for the rest of the year by 10% or more. Conversely, if a key product slows down, the forecast could drop. At an aggregate level (total account), your forecast and Amazon’s might align over time, but at the item level there could be big swings. Monitor how Amazon’s signals respond to real sales; this can at least alert you when Amazon’s view of demand has materially changed.

- Anticipate PO Timing by Coverage: Rather than trying to guess exact PO quantities each week, focus on weeks of cover and sell-through trends. A practical rule: if Amazon’s on-hand inventory for a product is getting down to ~3-4 weeks of cover (or less) and sales velocity is steady or growing, you can expect a purchase order soon. Amazon typically reorders when their system projects that stock will run out in a few weeks (they don’t want a stockout). So keep an eye on the sellable on-hand units Amazon has (from the Vendor Central inventory report) relative to average weekly sales. If you see it dip, be prepared for a reorder.

- Consider Lead Time and Events: If a big seasonal event is coming (Prime Day, Black Friday) and your product usually spikes, Amazon often pulls POs forward ahead of the event. For example, they might place a larger order 4-6 weeks before Black Friday to build inventory. Your forecast should account for this pre-event load-in. Conversely, if you’re not participating in an event but others in your category are, Amazon might temporarily de-prioritize reorders for you during that period (their warehouses focus on event items). After the event, they could resume normal ordering.

- Be Aware of Hidden Constraints: Sometimes you’ll scratch your head as to why Amazon isn’t ordering despite strong sell-through. There are invisible factors that might be at play:

- Fulfillment Center (FC) constraints: e.g., your items ship from a specific type of warehouse (hazmat, heavy/bulky FCs) and that warehouse is temporarily full or overwhelmed. Amazon might hold off ordering until capacity frees up.

- Overstock in related products: If Amazon over-ordered a similar item (maybe from another vendor) and it’s sitting in the warehouse, they may pause orders for your item to avoid excess inventory.

- System flags: Occasionally, Amazon’s system might flag an ASIN (retail readiness issues, supply risk flags, etc.) which slows orders.

These are hard to detect, but if a product’s PO cadence breaks for no obvious reason, consider these possibilities. This is where communication with Amazon (or having a vendor manager) can help, though often you won’t get a clear answer.

- Fulfillment Center (FC) constraints: e.g., your items ship from a specific type of warehouse (hazmat, heavy/bulky FCs) and that warehouse is temporarily full or overwhelmed. Amazon might hold off ordering until capacity frees up.

In summary, translating to sell-in involves informed guesswork: use your sell-out forecast as the demand ceiling, monitor Amazon’s inventory and forecasts as clues, and remember that Amazon will err on the side of under-ordering (they’d rather be a little short than heavily overstocked). Your job is to fill the gaps with agility and contingency plans, as discussed next.

Ensuring In-Stock Availability: Agility Over Perfection

Because you cannot perfectly predict Amazon’s every move, the emphasis shifts to staying agile and preventing stockouts. A multi-pronged strategy is needed: forecasting is one part, but inventory buffers and rapid response capabilities are equally important. Here are best practices:

- Maintain a Safety Stock Buffer: Justin recommends holding roughly 3–4 weeks of safety stock beyond your forecasted demand. In other words, after you’ve ordered (or produced) enough inventory to meet the forecast, have an extra few weeks of supply in your warehouse. This buffer accounts for any demand underestimation or delays in Amazon’s reordering cadence. It’s especially crucial in Amazon 1P because if Amazon suddenly sells through faster than anticipated, you can quickly fulfill the next PO without scrambling for production. The exact amount of safety stock might vary by product (consider shelf life, storage cost, etc.), but three to four weeks is a common rule of thumb for many brands.

- Pipeline and Lead Time Awareness: Safety stock also buys you time given typical vendor lead times. Remember that when Amazon issues a PO, you often have anywhere from 1 to 4 weeks to deliver (and during peak times or shipping delays, it might effectively be ~2-4 weeks before Amazon receives and stocks it). If you only produce or inbound goods after a PO, you could easily stock out on Amazon while waiting. A filled pipeline means you have product either ready or already en route to Amazon. The safety stock at your warehouse covers sales in the interim.

- Use Direct Fulfillment as a Backup: One powerful contingency is Amazon’s Direct Fulfillment (DF) program (often called dropship). This allows vendors to ship products directly to the end customer when Amazon’s warehouses run out. Setting up DF capability can significantly reduce lost sales when Amazon’s DC stock is depleted. Justin calls this “massively important” as a backup. You can run a hybrid model – primarily selling via regular POs (warehouse stock), but keeping Direct Fulfillment turned on in the background. In normal times, Amazon’s algorithm might prefer its own stock, but if that goes to zero, the DF offer kicks in so the product stays available for purchase. This can bridge the gap during those 2-3 weeks it takes to produce or ship more inventory to Amazon.

- Tip: Even if you don’t want DF on 24/7, strongly consider enabling it during peak seasons or promotions. For instance, ahead of Prime Day or Q4, have DF active as a safeguard. If Amazon’s sell-through exceeds expectations and their warehouse runs out, DF can salvage the sales. Many vendors use DF seasonally – turning it on for critical weeks. Just ensure your own fulfillment operations can handle single-item direct shipments in volume if needed (DF requires packing individual orders, similar to e-commerce fulfillment).

- Tip: Even if you don’t want DF on 24/7, strongly consider enabling it during peak seasons or promotions. For instance, ahead of Prime Day or Q4, have DF active as a safeguard. If Amazon’s sell-through exceeds expectations and their warehouse runs out, DF can salvage the sales. Many vendors use DF seasonally – turning it on for critical weeks. Just ensure your own fulfillment operations can handle single-item direct shipments in volume if needed (DF requires packing individual orders, similar to e-commerce fulfillment).

- Escalate When Necessary: If you see an impending stockout (Amazon’s stock is nearly gone and no new PO has come), don’t hesitate to escalate through any channel available. This might include reaching out to your Amazon Vendor Manager or In-stock Manager (if you have one), opening a high-priority case in Vendor Central, and even emailing any Amazon contacts you’ve worked with. While Amazon’s algorithms usually trigger orders, they’re not infallible – and occasionally POs get stuck or skipped due to system errors or oversight. Pushing an escalation won’t always yield a manual order, but it can alert Amazon to issues. Justin’s advice: “any lever that you can pull…pull on it” – in other words, be proactive and persistent in communicating critical stock needs. It’s better to be “a squeaky wheel” than to quietly stock out.

- Plan for the Unplanned (Agility): The overarching theme is agility over perfection. You will rarely forecast exactly what happens – the real world will throw curveballs (a sudden influencer-driven surge, supply delay, algorithm change, etc.). The winners are those who detect changes quickly and adjust. This means:

- Monitoring sales and inventory daily or weekly – so you notice if something is 20% above forecast two weeks in a row (time to raise the forecast and send more stock!) or if a product is suddenly slowing (maybe avoid sending too much).

- Being ready to pivot production or reallocate inventory. If one product line takes off, can you divert inventory from a slower seller or rush a reorder from your supplier?

- Reforecast frequently. A forecast is not set in stone for the year. Justin suggests revisiting forecasts with some regular cadence – e.g. do a monthly forecast vs actual review and update projections for the next 2-3 months on a rolling basis. This rolling forecast method means you’re always incorporating the latest data (internal and Amazon’s feedback signals) into your plan.

- Monitoring sales and inventory daily or weekly – so you notice if something is 20% above forecast two weeks in a row (time to raise the forecast and send more stock!) or if a product is suddenly slowing (maybe avoid sending too much).

In short, staying in stock on Amazon requires a mix of good forecasting and nimble execution. The best forecasts give you a starting point, but real-world agility keeps you ahead of stockouts when (not if) reality differs from the plan.

Tools and Best Practices for Forecasting

Forecasting can be done with anything from a simple spreadsheet to advanced software. The choice of tool is less important than the approach behind it. Here are some tool tips and process best practices:

- Embrace Spreadsheets if They Work: There is nothing wrong with using Excel or Google Sheets for your forecasting model. In fact, spreadsheets are extremely flexible for building custom models, running “what-if” scenarios, and tweaking assumptions on the fly. Many successful vendors still rely on a well-constructed spreadsheet that pulls in sales data and allows manual input of upcoming events and adjustments. If you’re comfortable with it and it produces results, stick with it. Just ensure it’s not so complex that it becomes error-prone or hard to update.

- Evaluate Forecasting Software (Carefully): Numerous e-commerce analytics platforms and Amazon vendor tools offer forecasting modules. These can automate data gathering (pulling Amazon reports) and use algorithms to project trends. They are worth exploring, especially as your catalog grows large. However, avoid “black box” tools: if a software won’t let you see or adjust the assumptions (for example, it blindly spits out a number without explaining if it assumed 5% seasonality uplift or a 2-week lead time), be cautious. You need the ability to challenge and refine the forecast. As Justin advises, the tool should let you play with variables – e.g., “what if our ad spend increases by 20%?” or “what if lead times worsen next quarter?” – and see the impact. The best tools combine automation with transparency and control.

- Operate Cross-Functionally: One of the biggest mistakes in forecasting, per Justin, is to “operate in a silo.” Don’t isolate the forecasting process to just one analyst or the supply chain team. Instead, create a small forecasting team or routine meeting that includes stakeholders from marketing, sales/account management, supply chain, and finance. This group can provide input and also needs to hear what the forecast is saying. For example, marketing might inform the team of an upcoming campaign (so forecast should adjust up), and the supply chain lead might warn of a production delay (so forecasted sales might not be deliverable unless resolved). Having everyone aware ensures there are no surprises like “We stocked out because nobody told us the ad went viral”. It also helps in getting organizational buy-in for holding extra inventory or spending on safety stock – if all departments understand the reasons (and risks of not doing so), it’s easier to align on inventory decisions.

- Establish a Regular Review Cadence: Treat forecasting as an ongoing process, not a one-time task. A good practice is to set a monthly or quarterly forecast review where you compare forecast vs. actuals for the past period and adjust the forward looking forecast. Amazon’s market conditions can change quickly (new competitors, Amazon policy changes, etc.), so your April plan might look very different by July. Continuously refine your model’s accuracy by learning from errors. For instance, if you see that for the last three months, Amazon has been ordering 15% less than your predicted demand (perhaps due to conservative buying), you might incorporate a 0.85 factor on your future sell-in projection for planning purposes. The key is to re-evaluate with rigor – don’t set and forget the forecast. Make it a living document that evolves with new information.

- Document Assumptions: Whether in a spreadsheet or software, clearly document the assumptions (growth rates, campaign impacts, seasonality multipliers, etc.) behind your forecast. This makes it easier to explain to management (or to Amazon, if needed) why you are planning a certain way. It also allows for better post-mortems (e.g., “we assumed +50% growth from the summer promotion, but it delivered +100%, which is why we ran short”). Learning from these will improve future forecasts.

By using the right tools and processes, you can significantly improve your forecast accuracy and preparedness. But remember that no tool is crystal ball – it’s about informed planning and then agile adjustment.

Handling Amazon Vendor Programs and Events

Amazon provides a few programs that can influence forecasting and ordering patterns, as well as events that cause demand spikes. Two notable ones discussed in the webinar were Bulk Buy offers and the Born to Run program. It’s important to understand how these work and when (or if) to leverage them:

- Bulk Buy Offers: This is a program where Amazon invites a vendor to sell a large quantity of product in a one-time bulk purchase order, usually in exchange for a steep discount (often ranging from 10% up to 50%+ off). Bulk buys are typically offered a couple of times a year to a vendor and are meant to boost Amazon’s stock on strategic items. Should you accept a bulk buy? It depends.

- On one hand, bulk buys can increase sales volume and cash flow immediately (you get a big order/invoice paid) and potentially improve your metrics with Amazon. In fact, a bulk buy discount can improve Amazon’s PPM (profitability) metric, which might encourage Amazon’s system to order more in the long run. Some vendors report that after doing a bulk buy, Amazon’s regular orders increased because the algorithm saw strong sales and good margins.

- On the other hand, bulk buys come at the cost of margin (you’re selling at a big discount). If your products were going to steadily sell anyway, a bulk buy might just cannibalize future orders at a lower price, hurting your bottom line without truly incremental sales. Justin noted cases where vendors growing 5–10% annually saw no major lift from bulk buys, meaning they essentially gave away margin for free. Moreover, a bulk buy often replaces or delays some of your regular POs: Amazon uses it to stock up, so the subsequent weeks’ orders may be smaller (though typically normal ordering resumes later and bulk buys don’t entirely replace weekly orders.

- Best Practice: Evaluate bulk buys on a case-by-case basis. Consider running a small test (if you have multiple ASINs, maybe accept a bulk buy on one to gauge impact). Track whether your sell-through and future orders truly increase or not. As one approach, use bulk buys strategically for new product launches or overstock clearance. For example, if you have a new variant that needs a push, a bulk buy can load Amazon up with inventory and improve its in-stock position and sales rank quickly. Or if you have excess inventory to clear (perhaps a seasonal item), a bulk buy can be a way to move it. If none of these apply and your demand is healthy, you might be justified in politely declining a bulk buy offer to preserve margins. In short, “test and learn” with bulk buys, and don’t feel obligated to take every offer.

- On one hand, bulk buys can increase sales volume and cash flow immediately (you get a big order/invoice paid) and potentially improve your metrics with Amazon. In fact, a bulk buy discount can improve Amazon’s PPM (profitability) metric, which might encourage Amazon’s system to order more in the long run. Some vendors report that after doing a bulk buy, Amazon’s regular orders increased because the algorithm saw strong sales and good margins.

- Born to Run (BTR): The Born to Run program is an invite-only Amazon Vendor program designed to help launch new products or new ASINs by letting the vendor request a big upfront PO. Essentially, a vendor can say, “Amazon, please order 500 units of my new product now, I’m confident they will sell through in 10 weeks,” even if Amazon’s system would normally order much less due to lack of history. If Amazon agrees, they place that PO and the vendor guarantees to support the sell-through (formerly Amazon required an ad commitment; now the vendor either takes back unsold units or pays a fee). This program is great to kickstart products that would otherwise launch slowly. However, as discussed in the webinar, BTR is not meant for regular replenishment or existing products, and Amazon has tightened the rules around it.

- In the past, some vendors tried to use BTR to, for example, get extra stock in before Prime Day or overcome Amazon’s conservative ordering on a well-selling item. Amazon noticed these “workarounds” and has since restricted BTR largely to its intended purpose – accelerating new product launches. Now, there are stricter limits (e.g., total value of BTR orders, time frames) and Amazon monitors sell-through; if the items don’t sell, the vendor either gets the inventory returned or pays a retention fee.

- Best Practice: Use Born to Run only for new product introductions or major item launches where you genuinely need to seed Amazon with more inventory than they would otherwise take. Ensure you meet the criteria (Amazon typically invites high-performing vendors with operational excellence). And be careful with your forecast for a BTR item – because if you overestimate and the product doesn’t sell within the given period (often 10 weeks), you will incur costs (either taking back product or paying a fee). Essentially, you’re betting on your new product; make sure you have the marketing support to drive demand so that the bet pays off (at least ~80% sell-through of that BTR inventory is a good target).

- In the past, some vendors tried to use BTR to, for example, get extra stock in before Prime Day or overcome Amazon’s conservative ordering on a well-selling item. Amazon noticed these “workarounds” and has since restricted BTR largely to its intended purpose – accelerating new product launches. Now, there are stricter limits (e.g., total value of BTR orders, time frames) and Amazon monitors sell-through; if the items don’t sell, the vendor either gets the inventory returned or pays a retention fee.

- Promotional Events and Spikes: Apart from formal programs, keep in mind the impact of big promotional events (Prime Day, Cyber Monday, Prime-exclusive sales, etc.) on forecasting. Amazon 1P will generally increase POs before events if you’re participating, but if you’re not, they might actually reduce orders and focus on others. Always review the calendar – if you know an influencer is featuring your product next month, expect a spike and either inform Amazon (Vendor Manager) or be ready via stock and DF. Similarly, if a competitor goes out of stock or you get a sudden #1 New Release badge, be ready for Amazon to ramp up orders (or conversely, if your product loses traction, Amazon may cut back quickly).

- Are Amazon’s PO Forecasts Available? A question came up about whether Amazon ever gives vendors a purchase order forecast report (essentially an estimate of future POs rather than customer demand). Justin confirmed that sometimes Amazon has pilots or special arrangements for certain vendors/products (often large vendors or critical products) where they do share more explicit ordering plans. These are not widespread and usually part of beta programs or vendor negotiations. For 99% of vendors, this is not something available in Vendor Central. So, do not count on Amazon providing you with a clear purchase plan – you’ll need to infer it from the signals and strategies discussed above. If you are lucky enough to be invited to a program that offers consistent ordering (or something like a joint business plan with minimum buys), that’s great – but always have your own forecasting process as a backup.

Communicating Forecast Uncertainty to Stakeholders

One often overlooked aspect of Amazon operations is internal communication – explaining to your company’s leadership and other stakeholders why Amazon forecasting and inventory management needs a different approach. Many executives are familiar with wholesale or traditional retail models where forecasts and orders are more predictable. They might expect Amazon to function similarly, which can lead to misaligned expectations. Here’s how to approach it:

- Educate on Amazon’s Model: Take the time to explain the “Amazon reality” to management – that Amazon doesn’t give you forecasts, can cut or increase orders with little notice, and that the vendor is responsible for reading the tea leaves of demand. Use concrete examples (maybe from your own business or industry news) to illustrate how Amazon’s just-in-time approach works. For instance, highlight that Amazon’s own system might show a high forecast but still not order due to an internal constraint, or that Amazon might drop a product from 8 weeks of cover to 2 weeks of cover and then suddenly reorder a huge amount. The goal is to ensure decision-makers understand that higher buffer stocks or faster response plans are necessary costs of doing business in this channel – not poor planning.

- Be the “Ambassador of Truth”: Justin used this phrase to emphasize not sugarcoating the uncertainty. It can be tempting to promise an exact number to appease a budget or to avoid sounding unsure. However, it’s better to set the expectation that forecasts are estimates and that you will manage ranges and risks. Stand firm on what it takes to succeed on Amazon – for example, if you know you need four weeks of extra inventory as a buffer, confidently advocate for it with data to back it. As Justin advises, “don’t give an inch when you’re trying to tell the truth on what it takes”. If you waiver, leadership might push back like “surely we don’t need that much safety stock” or “can’t we just trust Amazon’s number?”, which could undermine your efforts. Consistent messaging over time will help the organization internalize these unique challenges.

- Share Metrics and Misses: Use your reporting to keep everyone informed. Track metrics like Vendor Lead Time, Confirmation rate, Stock-out rates, etc., and share them. For example, if you avoided a stockout because you had DF as backup, call that out: “we sold additional 500 units via dropship that would have been lost sales – this is why we keep that option.” Or if a forecast was off because an unplanned event happened, frame it as “our forecast assumed X, but Y happened – here’s how we adjusted in response.” Over time, these real-world stories build understanding and confidence that while Amazon forecasting isn’t exact, it is being managed.

- Align on Agility as a Strategy: Finally, make sure the leadership recognizes that agility (and sometimes extra cost in the short term) is an investment for long-term success on Amazon. For instance, holding extra inventory might tie up capital, but the cost of stockouts (lost sales, lower Amazon ranking, potential lost market share) is worse. Show them the trade-offs. If you can quantify, do it: “Every 1 day out-of-stock on our top ASIN costs us $X in sales and hurts our search rank, which takes weeks to rebuild.” Therefore, spending $Y to expedite a shipment or air-freight goods in a pinch might be justified. When framed as protecting the business on Amazon, these agile moves sound less like fire-fighting and more like part of the plan.

Ultimately, internal stakeholders don’t need every gritty detail, but they do need to trust that Amazon 1P requires a different playbook. By communicating clearly and backing it up with data (and real examples), you can secure the support (and resources) needed to execute the forecasting and inventory strategies outlined above.

Conclusion

Mastering forecasting and in-stock availability on Amazon 1P is a balancing act between data-driven planning and responsive agility. You won’t get a perfect roadmap from Amazon – or as Justin McMillan put it, “you’re not getting into a situation where you know, come a particular date, you’re going to get X in purchase orders”. Instead, you build the best demand forecast you can with historical data and known inputs, use it to guide production and inventory decisions, and then continuously adjust as real sales and Amazon’s behavior unfold.

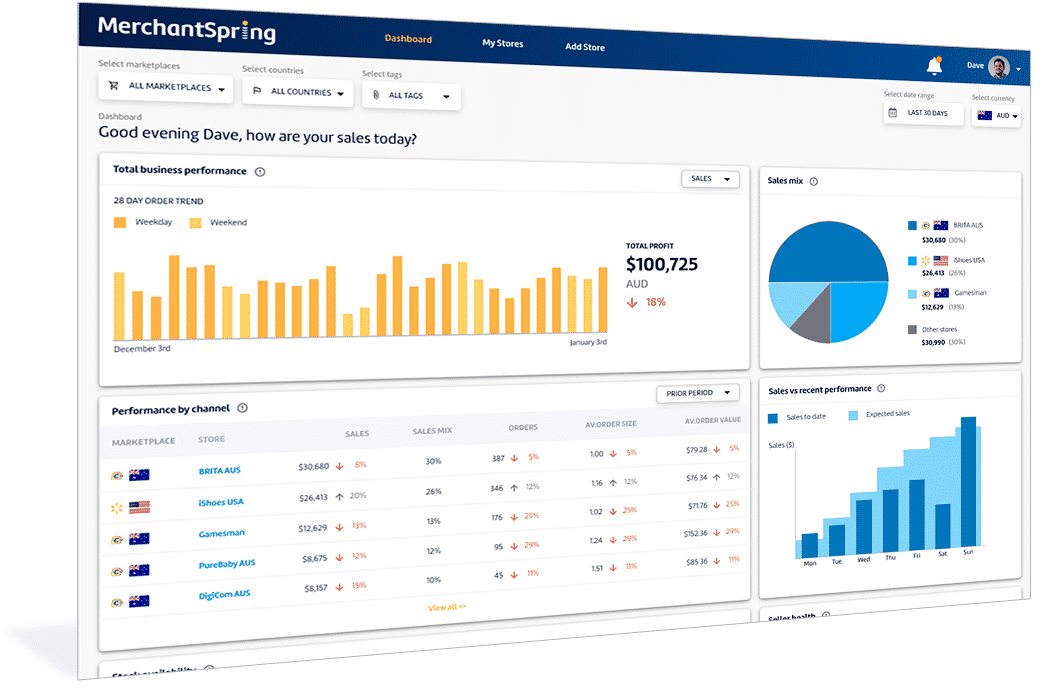

If today’s conversation with Justin McMillan resonated with your challenges, now’s the time to act. Connect with Justin on LinkedIn to dive deeper into Rebelution’s approach to vendor operations, or explore how MerchantSpring’s analytics solutions can help you monitor forecasts and improve performance. Visit merchantspring.io or reach out for a personalised walkthrough. Let’s turn uncertainty into an advantage.

-Jun-25-2025-02-55-19-0401-AM.png)

Add a Comment