Mastering Amazon Vendor Forecasting: 1P Purchase Order Planning, Safety Stock Strategy & Agility

Forecasting demand in Amazon’s first-party (1P) vendor channel is not for the faint of heart. One Amazon vendor even joked, “I don’t forecast anymore—I just brace for impact.” That half-joking, half-frustrated sentiment captures the challenge perfectly. Unpredictable purchase orders (POs), sudden demand spikes (hello, viral influencer moments!), and limited signals from Amazon can make inventory planning feel like a constant guessing game. Yet, accurate forecasting is mission-critical for vendors – it’s the difference between staying in stock and losing the Buy Box to a competitor.

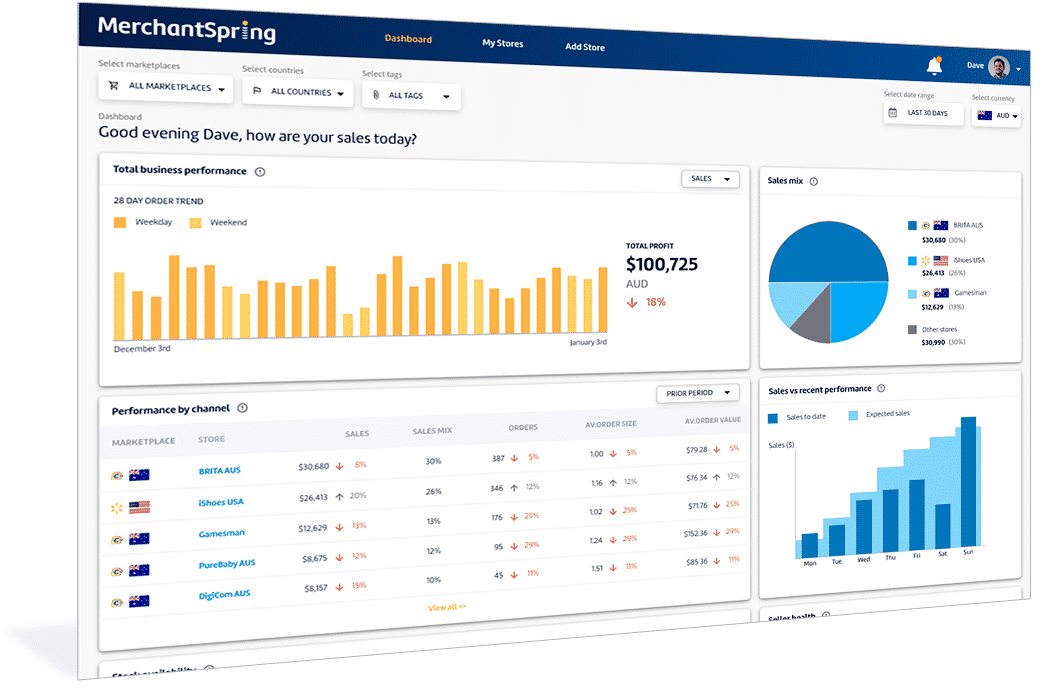

Caption: Data-driven Amazon 1P forecasting helps vendors turn chaos into clarity, keeping products in-stock despite unpredictable demand.

In a recent Marketplace Masters webinar, Justin McMillan – Co-Founder of Rebelution e-Commerce – tackled these forecasting challenges head-on. Drawing on his experience running a vertically integrated Amazon 1P agency out of Chicago, Justin’s approach blends strategy, real-world experience, and just the right tools. This blog post synthesizes Justin’s insights and expert strategies from that webinar, providing Amazon vendor professionals with a roadmap to forecast with confidence. We’ll explore how to forecast Amazon 1P sell-out, estimate Amazon’s POs, manage inventory risk, and prepare for demand surges – all while emphasizing why agility often matters more than precision in Amazon’s opaque vendor environment.

Whether you’re an Amazon agency professional or a brand vendor, mastering forecasting means turning chaos into clarity. Let’s dive into the key strategies and learn how to forecast like a pro in the 1P channel.

The Amazon 1P Forecasting Challenge

Forecasting in Vendor Central is a high-stakes puzzle. Amazon provides only limited demand signals, and its ordering patterns can swing wildly week to week. As one industry observer noted, vendor forecasting sometimes “feels like weather prediction in tornado season.” One week you’re flooded with POs; the next week, crickets. Then suddenly an influencer’s TikTok sends your product viral and Amazon sells out overnight. The complexity and importance of forecasting for Amazon vendors cannot be overstated – it’s about staying ahead of both demand volatility and Amazon’s ordering quirks.

Why is forecasting so critical? Simply put, it lets vendors anticipate demand rather than just react. “Vendors must not only meet customer demand but also anticipate it – this is where demand forecasting emerges as a crucial tool,” as one Rebelution e-Commerce expert explained. Good forecasts inform everything from production and procurement to marketing and finance. They help balance the tightrope between overstock (tying up capital and risking excess fees) and stockouts (missed sales, unhappy customers, and lost search rank). In Amazon’s ecosystem, poor forecasting can also mean costly chargebacks or lost vendor credibility. In short, forecasting is survival.

However, perfection is impossible in such an opaque system. Amazon’s own forecasts (like the P70/P80/P90 weekly demand projections) are just educated guesses – “probability levels are simply forecasts, not guarantees”. Even if Amazon provides a demand forecast, it’s not a promise of a purchase order. The onus is still on the vendor to plan wisely. Successful vendors, as Justin McMillan emphasizes, focus on agility – building a responsive supply chain and cross-functional team that can pivot quickly when reality deviates from the plan. “The goal isn’t a perfect forecast; it’s to avoid being blindsided by the unexpected,” Justin says. In the sections below, we break down core strategies he shared for forecasting sell-through, anticipating Amazon’s POs, managing risks, and staying nimble in the process.

Forecasting Amazon 1P Sell-Out Demand with Confidence

The foundation of Amazon vendor forecasting is predicting consumer sell-out – i.e. how many units Amazon will sell to customers (your product’s retail demand on Amazon). This sell-through forecast is the bedrock for everything else, since Amazon’s orders to you will ultimately reflect end-customer demand. But forecasting Amazon demand comes with unique twists:

-

Leverage Historical Data and Trends: Start with your Amazon Retail Analytics data or any sell-through reports to identify baseline sales velocities. Analyze at a granular level (ASIN or SKU) and look for patterns: seasonality, day-of-week trends, Q4 holiday surges, Prime Day boosts, etc. Remember that Amazon demand often ebbs and flows with seasonal events (Prime Day, Black Friday) more dramatically than D2C channels. Use at least 12 weeks (or more) of history to detect trends and capture variability. If you have access to Amazon’s forecast reports (like the 26-week forecast in Vendor Central), review them – but treat them as one input, not the gospel truth.

-

Account for Amazon-Specific Factors: Unlike forecasting for your own website, Amazon sales depend on factors outside your control. Competition and the Buy Box, for example, can drastically alter your sales overnight if a competitor runs out or undercuts on price. Changes in Amazon’s search algorithm or ad placements can spike or sink a product’s demand unexpectedly. Justin McMillan advises vendors to monitor marketplace variables closely – track competitor stock levels and pricing, keep an eye on category sales rank shifts, and note any changes in Amazon’s algorithm or ad policy. These signals help adjust your forecast up or down preemptively. No forecast should exist in a vacuum. As Justin put it, “Treat Amazon’s demand forecast as a living thing – it’s always evolving based on competition and algorithms.”

-

Incorporate Marketing and External Drivers: A common pitfall is assuming past sales alone predict future sales. Instead, integrate your upcoming marketing plans and any known external demand drivers. If your brand is launching a big Amazon Advertising campaign next month or if you’ve secured a spot on a morning TV show, factor that uplift into your projections. Influencer marketing deserves special mention – if a major influencer or celebrity is scheduled (or even likely) to feature your product, prepare for a possible demand spike (more on handling this later). The key is to adjust your baseline forecast to reflect planned promotions, pricing changes, or PR events. Amazon’s own tools don’t know about your off-Amazon marketing efforts, so it’s on you to layer that in.

-

Use Probabilistic Forecasting: Given the uncertainty, many vendors adopt a range forecast. Amazon’s P-level forecasts (e.g. P70, P90) essentially do this by giving a conservative vs. optimistic demand estimate. You too can forecast in ranges: e.g., “Base case = 1,000 units/month, but could be 800 on the low side or 1,300 on the high side.” This approach encourages planning for best and worst cases rather than one number. It’s especially useful when communicating with management – you can explain the assumptions behind each scenario (e.g. competitor enters market, or conversely a new ad campaign succeeds wildly). Scenario planning is an advanced but invaluable technique: “Prepare for different outcomes – higher-than-expected demand, supply disruptions – and have contingency plans”. In practice, that means if your optimistic scenario is coming true (demand trending above forecast), you already know how to ramp up production or reallocate inventory from other channels.

By forecasting sell-out with these methods, you create a solid demand plan. Justin McMillan’s no-nonsense tip here: build forecasts that are “approximately right” and update them often. It’s better to capture the trend and be ready to adjust than to obsess over decimal-point accuracy. In a volatile 1P environment, agility starts with a realistic, data-informed baseline for demand.

Estimating Amazon’s Purchase Orders (POs)

Forecasting consumer demand is step one; step two is figuring out how Amazon will translate that demand into POs for your products. This is where things get tricky – Amazon’s Vendor Central system often keeps you in the dark. Amazon typically places POs based on its own algorithms, considering factors like your sell-through rate, current Amazon warehouse inventory, vendor lead times, and even Amazon’s confidence in your supply. So how can you anticipate POs when Amazon doesn’t tell you much?

Analyze Past PO Patterns: Start by analyzing your historical PO data alongside sell-through. Often there’s a pattern: for example, Amazon might reorder when their weeks-of-cover falls below a certain threshold. Look for signals like order frequency (weekly, bi-weekly, etc.), typical order quantities, and how POs reacted to spikes or lulls in consumer sales. You might notice, for instance, that after a big sales spike, Amazon’s next PO was disproportionately large to replenish stock, or that Amazon skips orders when on-hand inventory exceeds X weeks of sales. Identifying these patterns helps you anticipate the next move.

Bridge the “Consumption vs. PO” Gap: A savvy strategy Justin highlighted is comparing end-customer consumption vs. Amazon’s purchase patterns. If you chart consumer sell-out vs. Amazon’s orders, any mismatch is revealing. One analytics provider noted that their tool allows vendors to analyze disparities between customer demand and Amazon’s PO patterns. Consistent gaps (e.g. Amazon ordering less than actual demand until a stockout is imminent) signal that you should plan extra buffer inventory or prompt Amazon for orders sooner. On the flip side, if Amazon routinely over-orders relative to sell-through, you might brace for potential overstock or even returned inventory. Modern vendor analytics dashboards (like iDerive’s 1P forecasting tool) claim to “foresee Amazon POs based on historical behavior with unparalleled accuracy” by crunching these data points. Even if you don’t have fancy software, you can manually approximate this: track how many weeks of sales each PO represented and how that changed seasonally or with stockouts.

Leverage Amazon’s Forecast (Carefully): In Vendor Central, Amazon provides a forecast report (usually a rolling 26-week outlook) with metrics like P70, P80, etc. Remember, this is a demand forecast, not a PO forecast. However, it’s still useful. Justin recommends using Amazon’s forecast as a starting point to estimate POs: for example, if Amazon’s mean forecast for next month is 5,000 units and they currently have 2,000 in stock, you might expect Amazon to order roughly the difference (3,000 units) spread across the weeks – if your lead times and performance are good. Always factor in your Vendor Lead Time (VLT). If your VLT is long, Amazon may place larger, less frequent orders to cover the extra lead time. If your VLT is short and you have a high instock rate, Amazon might order just-in-time in smaller chunks.

Communicate & Collaborate: Sometimes the best way to anticipate Amazon’s orders is to have an open line of communication. If you have a vendor manager or instock manager at Amazon, regularly share your own demand forecasts and marketing plans with them. While Amazon’s systems are largely automated, human input can sometimes prompt a manual adjustment or at least align expectations. For example, if you alert Amazon that you plan a major off-Amazon promotion (which will spike demand), they might increase their ordering proactively – but only if they know about it. Building this collaborative forecasting relationship can help “align your inventory forecasting with Amazon’s purchase orders” in a mutually beneficial way. In essence, treat Amazon as a partner in your supply chain forecasting: the more they trust your insights, the more smoothly your POs may flow.

Finally, maintain a buffer when forecasting POs. Recognize that Amazon’s ordering can and will surprise you. Always have a contingency: keep some extra inventory at your own warehouse or 3PL that you can quickly send if Amazon suddenly blows through their stock. Estimating POs isn’t about exactness; it’s about anticipating the likely range and being ready to respond if Amazon orders far more – or far less – than expected.

Managing Inventory Risk with Safety Stocks and Agility

Even the best forecasts are inevitably wrong to some degree. That’s why managing inventory risk is just as important as the forecasting itself. Justin McMillan stresses that vendors need to build resilience into their inventory planning. Two key elements of this are maintaining safety stock and being agile with supply chain decisions.

Set a Sensible Safety Stock: Safety stock is your insurance policy against forecast errors and supply disruptions. Amazon used to include a safety stock factor in its forecasts, but no longer does – “safety stocks are no longer calculated into the demand forecast”. Amazon expects vendors to handle buffering inventory on their own. So, determine a safety stock level for each product based on its volatility and importance. A common formula is to base it on max daily or weekly sales and your lead time (e.g. keep enough extra units on hand to cover the highest sales you might get during your replenishment lead time). High-priority, fast-selling items deserve a larger buffer, whereas slow movers might warrant minimal safety stock. One comprehensive guide suggests, “Maintain a buffer of inventory for your best-selling items to account for unexpected demand spikes.” This ensures that if an influencer spike or sudden surge hits, you have stock to ride the wave (and Amazon can quickly place a supplemental PO without waiting for production). On the flip side, don’t let safety stock become stagnant inventory – revisit levels each quarter based on the latest sales patterns.

Plan for Supply Chain Disruptions: Inventory risk isn’t just on the demand side; supply issues can bite you too. Forecasting should include contingency planning for scenarios like a production delay, a freight slowdown, or a raw material shortage. For example, if your primary manufacturer encounters problems, do you have a backup supplier ready? If your shipment gets stuck in port, can you air freight a small batch to Amazon? During the webinar, Justin shared real-world frameworks for contingency planning. The takeaway: identify your vulnerabilities and have a plan B (and C). If you forecast 5,000 units for a quarter, consider what if only 3,000 arrive on time – how will you allocate those? Or what if demand hits 7,000 – can your supply chain flex to deliver more? Scenario planning for these cases ensures you’re not scrambling last minute. Also, keep an eye on Amazon’s instock rate metrics and any chargeback trends (e.g. “PO On-Time Accuracy” chargebacks). If you see repeated issues, it’s a sign your current safety buffers or processes need adjustment.

Stay Agile and Responsive: Agility in inventory management means being able to respond quickly when something goes off-plan. This could mean expediting a purchase order from your supplier, reallocating inventory originally meant for another retailer to Amazon, or even temporarily pivoting to 3P (Seller Central) if Amazon stock runs out. Justin highlighted that sometimes the best forecast adjustment is a fast reaction. If a demand spike blows through your stock, immediately communicate with Amazon (and perhaps even temporarily list the item via FBM or Seller Central, if that keeps it available to customers). If Amazon’s POs suddenly slow down, find out why – check if maybe your item got flagged with a stranded cost or if Amazon is overstocked. In some cases, it might be prudent to escalate the issue with your Vendor Manager. For instance, if you know there’s a genuine consumer demand but Amazon’s system isn’t reordering (perhaps due to a system glitch or conservative algorithm), reach out to your Amazon contact with data on the lost sales due to stockouts. Escalating with a solid case can sometimes prompt Amazon’s team to manually intervene or at least clarify the situation.

To sum up, managing inventory risk for Amazon 1P is about expecting the unexpected. Use safety stock as your shock absorber and cultivate an agile mindset in your operations. As the saying goes, hope for the best forecast, but prepare for the worst – that way, you’ll keep the business running smoothly even when reality throws a curveball.

Handling Demand Surges and Influencer Spikes

In the age of social media, an unexpected shout-out from a celebrity or influencer can send your Amazon demand through the roof overnight. One of Justin McMillan’s webinar topics was how to handle these wild demand surges – the “influencer chaos” scenario. The truth is, you often can’t predict an influencer-driven spike with precision. But you can prepare for it.

Early Warning Systems: First, set up listening mechanisms for any signs of virality. Monitor social media mentions of your brand and products. If a TikTok or Instagram post about your product starts trending, you want to know immediately (there are tools and services that can alert you to sudden increases in mentions). Likewise, keep an eye on your real-time sales velocity in Amazon – a sudden hour-by-hour jump can tip you off that something is up. Amazon’s own analytics might not flag this instantly, so having a direct sales dashboard or a tool like Amazon’s Brand Analytics (if available to you) can help spot surges early.

Rapid Response Inventory Plan: When a spike hits, minutes matter. Justin shared a story of a vendor who noticed an influencer spike at 10 AM and by noon was sold out. The vendors who thrive in these moments have a predefined action plan. This could include: immediately routing any available inventory (in your warehouses or other retailers’ stock) to Amazon fulfillment centers, upgrading shipping methods, and if possible, activating a parallel Seller Central offer as a stopgap. For example, if Amazon’s retail inventory sells out, having your own Seller Central listing (FBM or FBA) as backup can keep the product available to customers – capturing sales and maintaining momentum until Amazon replenishes. Yes, Amazon prefers to be the seller (1P), but in a pinch, a 3P offer you control is better than a product page that’s completely “Out of Stock.”

Communication During Surges: It’s also wise to inform your Amazon Vendor Manager (if you have one) as soon as you detect a surge. Provide them data: “We’ve gone viral on TikTok, demand is up 300% in the last 24 hours.” They might help fast-track a purchase order or work with the instock team to avoid the dreaded stockout. Some vendors have even negotiated contingency plans in advance, such as keeping a small consignment stock at Amazon or in an Amazon-owned warehouse that can be released during sudden spikes.

Post-Spike Recovery: After the surge, regroup and update your forecasts. An influencer spike can lead to a new normal of higher baseline sales if the publicity has lasting effects (e.g. sustained social media buzz or increased brand awareness). Adjust your demand plan upward until data shows it settling. Also, analyze how your supply chain held up. Did you manage to get back in stock quickly? If not, what could be improved – more safety stock, better monitoring, closer coordination with Amazon? Each spike is a learning opportunity to refine your surge response playbook.

In essence, while you can’t always predict the next Oprah’s Favorite Things feature or TikTok craze, you can absolutely prepare for it. The vendors who plan for “unknown unknowns” will recover faster and capitalize on viral moments, turning a chaotic surge into a massive win rather than a stockout nightmare.

Tools and Technology for Amazon Vendor Forecasting

No discussion of forecasting would be complete without addressing the tools that can help. In the webinar, Justin McMillan highlighted that while there’s no one-size-fits-all software, leveraging the right tools can significantly improve accuracy and efficiency. Let’s look at some categories of tools and their pros/cons:

-

Amazon’s Native Tools: Amazon Vendor Central provides some basic forecasting and inventory planning reports (like the Demand Forecast report with P70/P80 metrics, instock rate dashboards, etc.). Pros: These are first-party data sources, free with your vendor account, and give insight into how Amazon is thinking. Cons: They are limited in granularity and predictive power. Amazon’s forecasts often lag reality and don’t account for external factors like your marketing campaigns. Use them as a baseline, but you’ll need to overlay your own intelligence.

-

Spreadsheets and Internal Models: Many vendors still rely on the trusty Excel (or Google Sheets) approach. They build custom models, pulling data from Vendor Central (sales, POs, inventory levels) and applying formulas for trends and seasonality. Pros: Full customization to your business nuances; flexibility to model various scenarios; low cost. Cons: Can be labor-intensive and error-prone; hard to scale as data grows. Still, for smaller brands or those just building a forecasting practice, a well-structured spreadsheet with statistical formulas (or built-in tools like Excel’s Forecast function) can go a long way.

-

Third-Party Forecasting Software: There’s a growing ecosystem of software focused on Amazon inventory forecasting and PO planning for vendors. Tools like SmartScout, CommerceIQ, Forecastly, Kinaxis, or Inventory Planner (among others) offer features like demand forecasting, automated re-order suggestions, and even probabilistic forecasting models. For example, iDerive’s vendor analytics tool (used by some agencies) boasts an “enhanced 1P PO Forecasting Dashboard” that visualizes customer consumption vs. Amazon PO patterns. Pros: These platforms can crunch large data sets, incorporate machine learning, and provide more accurate forecasts and alerting (e.g. flagging when you’re at risk of stockout). They often integrate directly with Amazon’s APIs for up-to-date info. Cons: They come at a cost, and not all tools are equal – some are geared more towards 3P sellers, so you’ll want one that explicitly handles Vendor Central quirks. Additionally, no tool can fully predict Amazon’s behavior, so they need oversight and fine-tuning. Justin’s advice here is to evaluate tools critically: look for those that let you input your own assumptions (lead times, planned promotions) and that can simulate “what-if” scenarios.

-

Collaborative Planning Systems: Larger vendors might integrate Amazon forecasting into their company’s broader Sales & Operations Planning (S&OP) systems or ERP software. This could be an advanced demand planning module (like SAP IBP, Oracle Demantra, or Anaplan) which treats Amazon as one of multiple channels. Pros: Holistic view – you can coordinate Amazon forecasts with retail, D2C, etc. Useful for companies balancing 1P and other channels to avoid conflicts (e.g. if Amazon demand surges, an S&OP system can reallocate inventory from elsewhere). Cons: Complexity – these systems are heavy and require good data governance. Also, they might not capture Amazon-specific metrics like instock % or chargebacks natively, so you have to customize them.

In summary, the best tool is the one you’ll actually use. Some Rebelution e-Commerce clients use a combination – for instance, an internal Excel model augmented by a third-party tool’s insights. The goal is to automate the routine parts of forecasting (data gathering, basic projections) so your team can focus on strategy and exceptions. As Justin quipped, “Spend less time chasing data, and more time making decisions with it.” A good toolset enables exactly that.

Building a Cross-Functional Forecasting Practice

Forecasting shouldn’t happen in a silo. One theme Justin McMillan underscored is that cross-functional collaboration is key to forecasting success in the Amazon 1P world. What does this mean in practice? It means sales, supply chain, marketing, and finance all need to be in the loop and contributing to the forecast process.

Consider setting up a forecasting task force or S&OP meeting specifically for your Amazon business. Include your Amazon account manager/agency team, demand planner or supply chain lead, marketing manager, and finance analyst. Each brings critical input: the marketing team knows about upcoming campaigns or influencer partnerships (demand drivers), the supply chain team knows production constraints and lead times, the finance team provides targets and cash flow considerations, and the Amazon account managers have insight into Amazon’s behavior and performance metrics.

In these cross-functional meetings, review the latest sales trends and the current forecast. Discuss variances: Did sales overshoot the forecast last month? Why? Perhaps marketing ran a last-minute promotion or a competitor went out of stock – lessons to feed into future forecasts. Is a new product launching? The product team can provide pipeline and initial response metrics to adjust projections. Worried about supply issues? The operations team should flag any potential delays or capacity issues so the forecast can be adjusted proactively (and Amazon notified if needed).

Agencies and vendors working together: If you are an Amazon agency professional managing 1P clients, you should champion this cross-functional approach. Encourage your client to involve you in their forecasting meetings, and likewise share marketplace intelligence with them. For example, as an agency you might see category trends (maybe a competitor’s product got delisted, implying Amazon demand for your client could rise). Bringing that to the table makes the forecast smarter. On the flip side, if the brand tells you their retail partner orders are down, that might free up inventory that could be shifted to Amazon if demand is there. This level of information sharing breaks the silos between Amazon operations and the rest of the business.

Another best practice is to document assumptions and decisions. Maintain a living forecasting document that notes “we increased Q3 forecast by 20% due to expected influencer campaign” or “assuming 10% lift in conversion after listing content overhaul in June”. This creates organizational memory and clarity, so if forecasts later deviate, you can trace back why and course-correct.

Finally, leadership buy-in is crucial. Ensure that leadership understands that Amazon forecasting is an ongoing, dynamic process – not a one-time number crunch. Educate them that flexibility is needed. Justin often reminds executives that on Amazon, agility and responsiveness trump static plans. If leadership empowers the team to adjust forecasts and inventory commitments on the fly (without a ton of red tape), the whole organization can move at “Amazon speed” when needed. In a nutshell, make forecasting a team sport, and your accuracy and agility will improve across the board.

Agility Over Precision: The New Mantra for 1P Vendors

Traditional forecasting culture in many companies prizes precision – hitting that exact number. But Amazon’s vendor ecosystem laughs in the face of rigid precision. The mantra Justin McMillan preaches is agility over precision. What does that mean? It means that being roughly right and quick to adapt beats being exactly right but slow to react.

Why agility? Because Amazon’s demand signals and ordering behaviors are often opaque and last-minute. You might have a near-perfect forecast model, but if Amazon suddenly changes an algorithm or a supply chain disruption hits, that perfect forecast can become worthless overnight. It’s better to foster an organization that can detect change and respond rapidly, than to boast about a forecast variance of 1% (which might have been pure luck!).

Justin shared an insightful perspective: “Think of forecasting not as a one-off prediction, but as a continuous feedback loop.” You forecast, you see actuals, you adjust – again and again. The companies that treat forecasting as a living process tend to stay more in-stock and suffer fewer surprises. They are constantly course-correcting. Those that set a forecast in stone and walk away for a quarter are often the ones saying “What happened?!” when an unforeseen event knocks them off course.

Another aspect of agility is decision agility. Empower your team to make quick calls when needed: expediting an order, reallocating budget to buy safety stock, pausing a marketing campaign if inventory is too low, etc. A rigid organization where every change requires ten approvals will simply be too slow for the Amazon pace. Culturally, it’s about embracing that forecasts will be wrong and that’s okay – as long as you catch the divergence early and act. In fact, Justin suggests measuring success not just in forecast accuracy but in response time. How fast did we react to that run on inventory? Did we catch the trend in days, or did it take a stockout to wake us up?

Finally, let’s talk about Amazon’s opacity. Vendors often complain (rightfully) that Amazon doesn’t share enough data or rationale behind POs. This is unlikely to change. So agility also means proactivity in the face of ambiguity. Instead of waiting for Amazon to tell you something (e.g. a forecast or a reason for cutting POs), proactively gather intelligence and test and learn. If Amazon cut your PO by 50%, check the retail pricing, check if a new competitor showed up, or if Amazon flagged an issue. Often you can deduce the cause and adapt your plan (maybe your price is above the market, signaling Amazon’s algorithm to reduce orders – you might need to adjust your cost or terms).

In summary, agility is the superpower for Amazon vendors. As one LinkedIn commenter put it, “forecasting [for Amazon] feels like tornado season” – you can’t control the storm, but you can build a house flexible enough to withstand it. So embrace forecasting as an agile, iterative practice. Get comfortable with course corrections, and cultivate a team that thrives in a dynamic environment. That’s how you win in the long run, even if each week feels like controlled chaos.

Conclusion: Forecast with Insight, Stay In Stock with Confidence

Amazon 1P forecasting will never be easy, but it can become a competitive advantage with the right mindset and approach. As we’ve explored, it’s about combining data-driven techniques (historical analysis, probabilistic models, tools) with human judgment and cross-functional collaboration. It’s about planning for the known and preparing for the unknown. Most of all, it’s about staying agile – ready to pivot when Amazon throws a curveball.

Justin McMillan’s parting advice to vendors: Don’t aim for forecasting perfection; aim for resilience. If you stay adaptable and keep your finger on the pulse of demand and supply, you can weather the ups and downs. The vendors who master this will enjoy higher in-stock rates, fewer surprises, and ultimately stronger growth on Amazon.

Want to learn more? This blog only scratches the surface of the insights shared in the Marketplace Masters webinar. For a deeper dive and real-world examples, watch the full webinar on-demand (courtesy of MerchantSpring) with Justin McMillan and Paul Sonneveld. Justin shares additional soundbites and frameworks that can help you forecast with confidence and keep your Amazon supply chain running smoothly. Check out the webinar here: Mastering Forecasting and In-Stock Availability – Webinar Recording.

By implementing these strategies, Amazon vendors and agency professionals can transform forecasting from a “guessing game” into a source of clarity and control. Here’s to forecasting smarter – and never just bracing for impact.

Connect with Justin McMillan on LinkedIn for more insights, explore the Rebelution e-Commerce site for Amazon 1P services, and visit MerchantSpring for analytics solutions and more webinars like this.

Add a Comment