The Amazon Logistics Survival Guide for North American Vendors

Overview

Optimising logistics on the Amazon Vendor platform can feel like navigating a high-speed highway—one wrong turn can lead to delays, cost overruns, or unhappy customers. For Amazon agencies and vendor managers, mastering the nuances of Amazon vendor logistics in North America is crucial to keeping clients’ operations running smoothly. In this recent podcast, we bring you expert insights from a recent Marketplace Masters webinar with Tessa Blumenthal and Jackson Licha of Global Overview. These Amazon logistics veterans unpacked how vendors can streamline their supply chain, avoid costly pitfalls (like chargebacks and delays), and leverage Amazon’s own network to full advantage. We’ll expand on their advice with a broader strategic narrative, giving you actionable strategies to improve on-time performance, reduce costs, and stay ahead of the curve in an evolving logistics landscape.

As an agency professional, you know that logistics can make or break an Amazon vendor’s success. From choosing between Amazon’s collect vs. prepaid shipping (or “We Pay” vs “They Pay”) to managing cross-border deliveries into Canada or Mexico, the decisions are complex. This guide synthesises the webinar’s core takeaways—like understanding freight allowances, improving pickup on-time accuracy, and adapting to Amazon’s new regional distribution model—into a cohesive playbook. We’ll also delve into practical tips for communication with carriers, preparation for peak seasons, and when (if ever) third-party logistics might beat Amazon’s in-house options. Let’s dive into the details!

Logistics Options for Amazon Vendors in North America

Amazon offers vendors multiple avenues to get their goods into fulfillment centers. The primary choice boils down to “We Pay” (collect) vs “They Pay” (prepaid) shipping terms. In “We Pay” (collect), Amazon arranges the freight pickup via its network of carriers (including Amazon-owned trucks) and the vendor pays a negotiated freight allowance percentage. In “They Pay” (prepaid), the vendor handles shipping via their own carrier, and Amazon isn’t directly involved in transport.

Tessa Blumenthal explains that the right option often depends on volume and service level. Higher-volume vendors may unlock additional Amazon programs under the collect model, such as:

- Full Truckload (FTL) Shipments: If you can regularly fill an entire truck, Amazon might route orders as full truckloads directly from your warehouse to specific fulfillment centers. This reduces handling and often costs less per unit than LTL.

- Drop Trailer Programs: For very large vendors, Amazon can station an empty trailer at your facility to be loaded at your convenience. Once it’s full, Amazon swaps it with an empty one. This eliminates strict pickup appointment windows and keeps your dock flowing smoothly.

- Pallet Order or Bulk Programs: In some cases, Amazon may allow pallet-level ordering, where they purchase in full pallets to streamline receiving. This works in tandem with programs like FTL to maximise efficiency.

- Direct Fulfillment (Dropship): Also known as Amazon’s dropshipping program, this allows vendors to ship individual customer orders directly from their own warehouse (acting almost like a Seller fulfilled Prime). It’s great for extending selection or avoiding out-of-stock scenarios, but your warehouse must meet Amazon’s strict direct fulfillment metrics (fast shipping and real-time inventory updates) to qualify.

- Direct Import: If your products are manufactured abroad, Amazon might set up a direct import program. In this case, you’d send container shipments from, say, China or Mexico directly to Amazon’s network. Amazon often negotiates this as part of vendor terms (it usually requires high volume and may involve discounts or different freight terms for Amazon).

For smaller vendors, standard Less-Than-Truckload (LTL) or Small Parcel shipments under the collect model are common. Amazon’s in-house carrier (or partner carriers) will pick up your goods within the assigned ship window. Under prepaid terms, you’d arrange an LTL freight carrier or parcel service yourself.

Qualification criteria: Many of these enhanced programs have eligibility thresholds. Volume is a key factor, as Tessa noted. For example, full truckload and drop-trailer arrangements typically require a steady flow of orders that can fill trucks regularly. Direct Fulfillment requires passing a test period to prove your warehouse can ship orders quickly (often within 24 hours) and meet Amazon’s customer service levels. The North American Direct Import option may hinge on having enough volume to fill ocean containers and a track record of reliable supply. If you think your client might qualify for an Amazon program, reach out to Amazon or your vendor manager – it never hurts to ask what might be available.

Amazon vs. Third-Party Carriers: Weighing the Pros and Cons

On paper, letting Amazon handle inbound shipping (collect/We Pay) sounds like a no-brainer. Amazon’s scale means they negotiate excellent freight rates, and they take on much of the hassle. When Amazon’s carriers manage pickup and transport, Amazon bears responsibility for transit delays – vendors are only accountable for having orders ready on time and properly documented for pickup. This can greatly reduce a vendor’s risk of delivery-related chargebacks.

“If a vendor can use Amazon services, it’s much better... unless you have your own dedicated truckers and a really good contract, we’re actually seeing third-party carriers struggle.” — Jackson Licha, Vendor Operations Manager at Global Overview

There are situations, however, where an independent logistics strategy might be considered. A few large vendors (think Fortune 500 manufacturers) have their own shipping fleets or long-term 3PL contracts with guaranteed service levels. These companies might achieve equal efficiency and slightly lower costs on their own, especially if they ship to many retailers besides Amazon. But for the vast majority of vendors, Jackson Licha confirms that Amazon’s in-house logistics outperform third-party providers on reliability and cost. Unless your client has extraordinary logistics capabilities in-house, sticking with Amazon’s network is usually the smart play.

Here are key factors to consider when comparing Amazon’s collect service vs. third-party (prepaid) shipping:

- Cost & Freight Allowance: Amazon will charge a freight allowance on purchase orders under collect terms. This is typically 2–5% of the PO cost for many vendors. That percentage covers all shipping into Amazon. Compare this to quotes from 3PL carriers for your lanes. Often, Amazon’s economies of scale make that percentage very competitive, especially when you factor in the time and labor saved by not managing freight. (Even on prepaid terms, note that Amazon may apply a smaller freight allowance for their internal redistribution costs, as Jackson mentioned).

- Risk & Accountability: Under collect, vendors must meet pickup readiness metrics (have the shipment prepared by the ship window, proper labels, on-time ASN submission) – but Amazon is accountable for the transit once the carrier picks up. Under prepaid, vendors are fully on the hook for delivering into Amazon’s fulfillment center on time. Any carrier failure or delay can lead to chargebacks for late delivery, and Amazon’s system won’t automatically excuse it just because your 3PL had an issue. In other words, collect transfers the ownership of risk to Amazon’s side.

- Visibility & Support: Amazon’s logistics system provides more internal visibility. If Amazon’s carrier has your pallets, Amazon knows where they are in their network. They can update receive times and adjust for delays better. With a third-party carrier, Amazon’s systems only know something arrived when it checks in at the dock. You also lose Amazon’s internal support – as Jackson noted, with Amazon carriers you must communicate through Amazon’s portal (you can’t just call the driver). But at least Amazon can be pressed for answers if their own carrier fails; with an external carrier, Amazon simply says “it’s your responsibility.”

- Flexibility: Using your own carrier gives you flexibility to choose pickup times, prioritise certain POs, or use premium shipping if needed. It can make sense if you have a specialised product that requires climate-controlled trucks or handling that Amazon doesn’t offer. But these cases are niche. In general, Amazon’s network is robust enough to handle most needs, including refrigerated shipments (Amazon has carrier options for that if required).

Bottom line: For most vendors, Amazon’s in-house logistics options are the path of least resistance and often the most cost-effective. The collect (We Pay) model simplifies operations by letting Amazon orchestrate the complex dance of pickups, linehauls, and delivery appointments. Third-party logistics only tend to win out if a vendor has exceptional capabilities or needs outside Amazon’s scope. As Jackson summed up, unless you have a dedicated fleet and guaranteed service, it’s tough to beat Amazon’s system.

Common Logistics Challenges (and How to Mitigate Them)

Even with Amazon handling the heavy lifting, logistics is never completely hands-off for vendors. Agencies should proactively monitor and manage key steps in the process to avoid pitfalls. Here are the most common challenges Amazon vendors face in North America – and strategies to address them:

- Tight Pickup Windows & Carrier No-Shows: Amazon assigns specific ship windows for each purchase order. Typically, you might get 1–3 days in which a carrier will come. A frequent complaint is carriers missing pickups or arriving late. Jackson highlighted that on-time pickups are the number one issue vendors report. A nationwide driver shortage means carriers sometimes prioritise other pickups or simply run behind schedule.

Mitigation: Always have freight ready early in the window, and use Amazon’s portal to communicate immediately if a pickup is missed. Document everything (dates, times, any carrier communications) so you can dispute chargebacks if Amazon tries to levy a “PO On-Time Accuracy” penalty due to their carrier’s failure. Most importantly, build in a buffer – if possible, don’t wait until the last day of the window to have goods ready. Some savvy vendors even over-estimate lead times slightly so POs are issued with a comfortable window. While you can’t directly call Amazon’s contracted drivers, you can and should hound Amazon’s support if pickups slip. In critical cases, escalate through your vendor manager to get a truck rescheduled.

“The number one thing is making sure you have a good communication channel, and number two is making sure freight is ready when it’s supposed to be… those two things are probably 90% of the challenges we face in the US.” — Jackson Licha, Vendor Operations Manager at Global Overview

- Communication Gaps: Unlike working with your own trusted freight company, with Amazon’s carriers you often feel one step removed. You can’t just call the trucking company dispatch directly for updates; you must go through Vendor Central queries or the Carrier Central interface.

Mitigation: Set up a clear internal process to track each shipment. As an agency, establish an SOP for your vendor clients: as soon as a routing request is submitted, mark the ship window on a calendar. If no carrier shows by midpoint of the window, begin sending chasers through Amazon’s system. Ensure your client’s warehouse staff is trained to know who to alert when something goes wrong. Quick communication to Amazon can sometimes prompt them to send a backup truck if one fails. Basically, stay proactively engaged – don’t assume “no news is good news” during a ship window.

- Carrier Capacity Crunches (Peak Season and Weather): In North America, Q4 holiday peak is famously challenging. There are far more loads than trucks, and winter weather can throw curveballs. Hurricanes, blizzards, wildfires – these can all disrupt regional logistics for days or weeks. Even Amazon’s network feels the strain during holiday surge weeks.

Mitigation: Plan far ahead for peak. Tessa strongly recommends locking in holiday promotion plans at least 5+ weeks in advance. Why? Amazon’s demand forecasting will then generate stock orders earlier, giving you more lead time to ship before the crunch. If Black Friday is coming, ideally you want those POs in September or early October. Additionally, coach vendors that Amazon’s carriers will be prioritised at the docks during peak.

As Jackson revealed, “Amazon’s going to prioritise their own collect carriers”. This means if you try to switch to your own carrier last-minute in Q4 thinking it’ll be faster, you’ll likely find your trucks waiting in line behind Amazon’s. Stick to the plan, ship early, and use Amazon’s network to get preferred treatment at the fulfillment centers. And in case of known weather events (e.g. a forecasted hurricane), communicate with Amazon for possible extensions or alternate plans ahead of time.

- Inbound Compliance Errors: Sometimes the issue is on the vendor’s side – mislabelled pallets, incorrect Advanced Shipment Notifications (ASNs), or poor packing that causes damage. These lead to delays and chargebacks upon delivery.

Mitigation: Rigorously train warehouse teams on Amazon’s requirements. Every carton needs the proper shipment label; every pallet must have a pallet ID label; pallets should be shrink-wrapped to prevent falling apart in transit. Double-check that the ASN (Amazon Shipment ID / ARN) transmitted in Vendor Central matches exactly what is physically sent. A common mistake is sending a different quantity than in the ASN – a sure trigger for chargebacks.

Also, accurately measure and declare shipment dimensions/weights when booking freight. If you underestimate pallet count and Amazon’s truck arrives to find more goods than expected, the excess might be left behind. Conversely, overestimating could leave the truck half-empty (inefficient for Amazon and could delay consolidation with other vendors). The takeaway: sweating the small details in prep pays off with smooth receivals.

- Cross-Border Complexities: One question from the webinar audience asked how to stop Amazon U.S. from transferring inventory to Canada. Indeed, under the North American Fulfillment Network (NAFN), Amazon (once they buy your product) can move it between the U.S., Canada, and Mexico to meet demand. This can cause issues if your product isn’t compliant outside the U.S. (e.g. needs French labeling for Canada).

Mitigation: If a vendor truly doesn’t want Amazon to export their items, they must formally request to opt out of NAFN. Tessa noted this is only granted in special cases (usually legal or regulatory reasons). Otherwise, assume that Amazon may ship some of your stock across borders. To prepare, ensure products meet any bilingual packaging requirements for Canada and consider the duty implications (Amazon handles the logistics, but vendors should be aware of any added costs in their agreements). On the flip side, if selling to Canada/Mexico is a positive, vendors can strategically use NAFN to expand reach without handling international shipping themselves – Amazon does it for them as long as inventory is available in U.S. warehouses.

- Unexpected Disruptions & Disputes: Despite best efforts, things sometimes go wrong: a truck breaks down, a load is lost, a warehouse refuses delivery due to congestion. This is where chargebacks and disputes come in. The “PO On-Time” chargeback (for late delivery) is one of the most common and costly. Jackson pointed out Amazon’s system has gotten stricter and “more difficult to dispute” these lately.

Mitigation: Document every step of a shipment. Keep copies of BOLs, timestamped photos of goods ready, screenshots if Amazon’s portal shows no appointments available, etc. If a delay occurs due to Amazon’s side (e.g. their carrier arrived late or a fulfillment center rescheduled your appointment), gather proof. File disputes as soon as the chargeback hits – the fresher the event, the better Amazon’s support can investigate.

Being proactive is crucial: some vendors only discover issues when it’s too late to fight. As an agency, implement a monthly audit process of all chargebacks and shortages. This way, you catch problems early and can compile the needed evidence (and coach the client on preventing repeats). It’s essentially an ongoing hygiene task in Amazon vendor management.

Strategies to Improve Performance and Cost-Efficiency

Having covered challenges, let’s pivot to proactive strategies that elevate your logistics performance. These are the areas an Amazon agency can really add value for vendor clients, by implementing systems and foresight that avoid firefighting:

- Optimise Freight Allowance and Terms: During annual vendor negotiations, analyse the freight allowance Amazon is charging versus your actual freight cost if you were to ship yourself. Sometimes there’s wiggle room to negotiate a lower percentage, especially if your product dimensions or lanes change significantly. Also, consider requesting beneficial programs: if your client’s volume has grown, approach Amazon about moving from LTL to full truckload, or joining the drop trailer program. Both you and Amazon save money when freight moves in fuller loads, so Amazon often supports these transitions without extra fees. Make the business case: show them the volume and how it would reduce touches. It’s a win-win that can minimise damages and improve timeliness too.

- Leverage Data & Forecasting: One of the webinar’s big-picture insights was Amazon’s drive toward regional warehouses and AI-driven distribution. Amazon’s algorithms are increasingly ordering product into specific regions of the country to keep it closer to customers and support one-day delivery promises. This means vendors might see smaller, more frequent POs distributed across multiple fulfillment centers.

To stay ahead, analyse Amazon’s ordering patterns for your products. If you notice, for example, a trend of POs going to four different FCs in different regions, adjust your production and inventory planning to match. It may be wise to stock goods in multiple staging warehouses or work with 3PLs that have national coverage, so you can feed Amazon’s distributed orders without delays. Additionally, lock in your promotional plans in Vendor Central early (coupons, deals, etc.), as Tessa suggested, because Amazon’s forecasting will then place bigger orders in anticipation. This helps avoid last-minute scrambling.

- Just-in-Time Inventory Mindset: Amazon generally operates with a lean inventory philosophy – they don’t want excess stock sitting idle. Tessa noted that “sitting inventory is waste” in Amazon’s eyes. Agencies should help vendors strike the right balance: ship enough to stay in stock, but not so much that Amazon’s warehouses overflow (which can trigger Amazon to curtail orders). Use tools or reports to monitor Amazon’s instock rates and sell-through. If Amazon consistently runs out before the next PO, that’s a problem – work with the vendor to either request larger POs or consider direct fulfillment as a backup.

Conversely, if Amazon is slow-moving certain items, the vendor might proactively pause marketing to allow sell-through, preventing returns or Overstock charges. A nimble, data-driven approach ensures optimal inventory turns that keep products available without bloating supply. And always keep an eye on lead times: if overseas transit times increase or domestic freight slows, adjust the planning cycle accordingly so Amazon’s ordering models can adapt.

- Strengthen Warehouse Readiness: We touched on compliance, but it’s worth emphasising process improvement at the vendor’s warehouse. Implement a daily routine for checking new purchase orders and their ship windows. Prioritise picking and packing for those with the earliest deadlines. Create checklists for labelling and ASN creation to reduce human error. It can also be valuable to invest in training or technology: for instance, using an ASN integration tool or EDI system that automatically confirms when Amazon pickups are scheduled. Redundancies like these help avoid the “oops, we forgot to confirm the routing request” scenarios that lead to missed pickups.

Another tip: over-communicate with Amazon’s carrier on the day of pickup. Vendor Central might show a carrier assignment and estimated date – ensure your warehouse team knows to expect them. If the day is nearly over and no truck, raise a flag immediately. Early action can sometimes get a same-day re-dispatch before the window closes.

- Prepare for the Unexpected: Given the realities of weather disruptions, strikes (e.g., trucking or port labour strikes), or COVID-like emergencies, have a contingency plan. Map out alternative warehouses or backup carriers (even under collect, you could request Amazon switch to another carrier if the primary fails repeatedly). Maintain a safety stock of your fastest-moving ASINs so a one-week transit delay won’t stock out Amazon entirely. It may also be wise to diversify port entries (for importers) or use both west and east coast fulfillment centers if possible, to hedge against regional events. The cost of holding a bit of extra inventory or setting up an alternate lane can be far less than lost sales from a prolonged disruption.

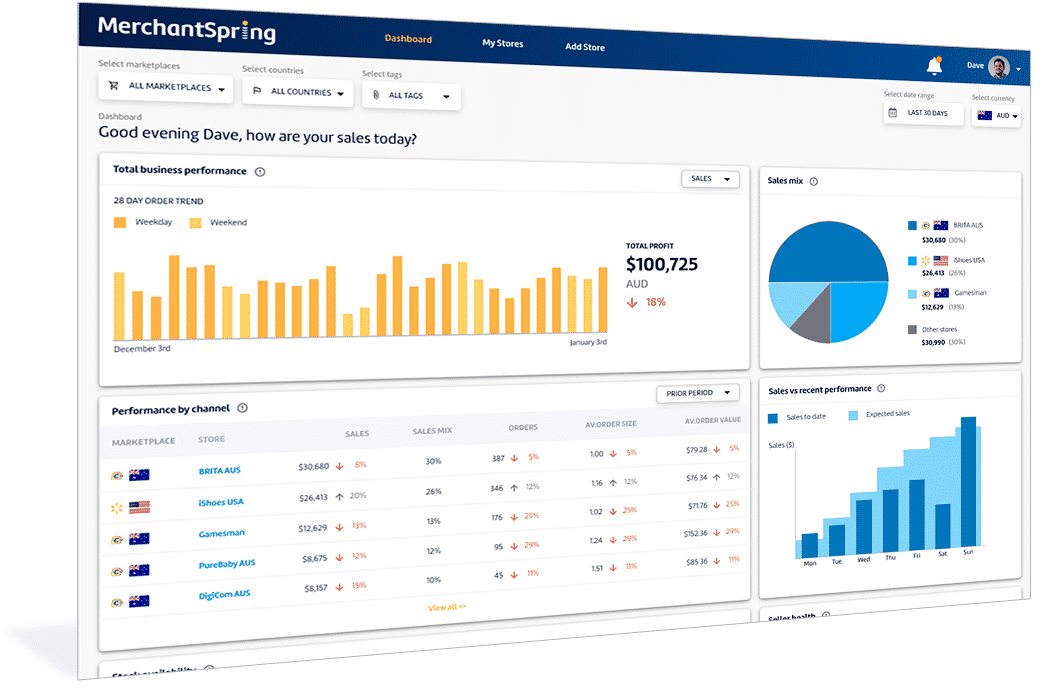

- Continuous Improvement via Analytics: Finally, use available data to continuously improve logistics performance. Amazon’s Vendor Central reports (or third-party analytics tools like MerchantSpring’s dashboards) can reveal patterns in chargebacks, lead time variability, and regional demand. For example, if you see repeated chargebacks for “ASN not received,” that points to a system integration issue you can fix. If Fill Rate is low (Amazon ordered 100 units but you confirmed only 50), dig into why – is it forecast issues, or did inventory not arrive from the factory? Solving upstream problems will make the downstream Amazon flow smoother. Many agencies provide value by running monthly logistics KPI reviews with their clients, addressing metrics like On-Time Pickup %, Transit Damage rates, and Vendor Lead Time trends. This transforms logistics from a headache into a strategic advantage.

Future Trends: Staying Agile in an Evolving Landscape

Amazon vendor logistics is not static – it’s continually evolving. One major change underway is the shift to a regional fulfillment network within the U.S. (some call this Amazon’s regionalisation strategy). Instead of shipping everything to a central network that redistributes nationwide, Amazon is steering vendors to send stock to specific regions (West, Central, East, etc.), hoping to cut down on cross-country transfers. As Tessa observed, Amazon is leaning on data science and AI algorithms for smarter distribution. Vendors should be prepared for more algorithm-driven ordering patterns, which might at first seem inconsistent (as Amazon fine-tunes the model). The key is to remain flexible. Be ready to adjust production or logistics flows as Amazon figures out the optimal regional balance. In the long run, this can lead to faster delivery to customers and potentially lower Amazon costs (which ideally makes vendors more profitable too, or at least reduces freight allowance pressures).

Another trend is Amazon expanding services like Amazon Freight and possibly Amazon Warehouse & Distribution (AWD) for vendors. (AWD is currently an offering for sellers to store inventory in Amazon’s facilities long-term, but Jackson hinted Amazon might push a similar concept to vendors.) The takeaway: Amazon wants as much control over the supply chain as possible, and they may roll out new programs that invite vendors to store or ship in different ways through Amazon’s ecosystem. Agencies should keep an ear out for such programs – joining early could give your clients an edge (for example, being a pilot user of a new inventory staging service).

On the flip side, consolidation and contraction of logistics capacity is happening too. Amazon built a lot of warehouse space in 2020-2021, then pulled back. Reduced space means stricter adherence to ship windows and potentially more rationed appointment slots for deliveries. Always assume that if you miss a slot, the next one might not be immediately available – another reason timely shipping is critical. Sustainability and efficiency will also shape logistics. Don’t be surprised if Amazon begins to measure and favour vendors who, say, maximise truck utilisation or use more eco-friendly packaging. It’s all part of driving waste (and cost) out of the system.

In short, staying agile and informed is part of the job. Keep communication channels open with vendor managers and Amazon ops contacts. Participate in Amazon’s vendor workshops or programs when invited – you’ll often catch wind of upcoming changes. By anticipating Amazon’s next moves (be it AI-driven ordering or expanded freight services), you can position your agency and clients ahead of the curve.

Conclusion & Call to Action

Optimising Amazon vendor logistics in North America requires a mix of strategic planning and tactical excellence. From the moment a purchase order drops to the final delivery at an Amazon fulfillment center, every step offers a chance to either improve efficiency or incur cost. By understanding the tools and options Amazon provides, avoiding common pitfalls, and applying continuous improvement, Amazon agencies can turn logistics into a competitive advantage for their clients. Remember, success lies in the details: accurate prep and labelling, vigilant follow-up on pickups, data-driven forecasting, and knowing when to lean on Amazon’s network versus when to innovate on your own.

Ultimately, smooth logistics are the backbone of vendor success on Amazon. By implementing the strategies outlined above, you can help ensure your clients’ products are always at the right place at the right time – with minimal cost and hassle. Now is the time to act: optimise those logistics processes, leverage Amazon’s programs to your advantage, and drive vendor performance to new heights.

In the ever-evolving world of Amazon operations, one constant is the value of expert insights and best practices. To dive even deeper and hear directly from the experts, consider watching the full webinar recording featuring Tessa and Jackson – it’s packed with real-world examples of solving logistics challenges. And if your team or clients need better visibility into their vendor performance, or help consolidating all these supply chain metrics, check out MerchantSpring’s Vendor Analytics platform for a unified view of sales, inventory, and operational KPIs.

Ready to take the next step? Watch the on-demand webinar for a deeper discussion and additional tips, and subscribe to our newsletter for more Amazon vendor best practices. If you have questions or need tailored advice on your Amazon vendor operations, don’t hesitate to contact us – our team of Amazon specialists is here to help you master the marketplace logistics game.

Add a Comment