Your Amazon Chargebacks Are Avoidable—Start Doing These 7 Things

Overview

Amazon chargebacks can feel like a constant battle for vendors – slashing into margins and disrupting operations. But chargebacks don’t have to be an unavoidable cost of doing business on Amazon. In fact, taking a proactive approach to prevent chargebacks can significantly boost your profitability (instead of always playing catch-up disputing them). According to one analysis, Amazon vendor chargebacks have cost vendors an estimated £4.8 billion worldwide, amounting to as much as 5% of revenue lost for some vendors(wakecommerce.co.uk). Clearly, the stakes are high, and prevention is critical.

In this episode, Manuel Kretschmer (Founder & MD of Amazon agency ama-X) shared how top Amazon vendors minimise chargebacks. You’ll learn essential strategies to stay compliant and turn these costly fees into opportunities for improvement. We’ll cover both a summary of key tactics and a deeper, SEO-optimised narrative explaining why they work, so you get actionable tips within a broader understanding of Amazon’s vendor ecosystem.

Why Amazon Chargebacks Happen (and Why Prevention Matters)

Amazon chargebacks are financial penalties Amazon deducts from vendor payments when the vendor fails to meet certain operational requirements(wakecommerce.co.uk). In Amazon’s highly automated fulfillment centers, any small exception – late shipment, missing label, inaccurate carton info – causes inefficiencies that Amazon “charges back” to the vendor to recover costs(wakecommerce.co.uk). Common chargeback causes include ASN errors, carton content mismatches, delivery issues (late or incomplete shipments), labeling problems, and packaging non-compliance(wakecommerce.co.uk).

While chargebacks might seem like a routine annoyance, they add up to significant profit loss over time(wakecommerce.co.uk). They can also signal deeper supply chain issues that, if left unresolved, hurt your reputation (e.g. products arriving damaged due to poor packaging leads to bad reviews)(wakecommerce.co.uk). As one vendor expert put it, “shortage claims can be disputed... but prevention is better than cure.”(khoocommerce.com) In other words, it’s far more efficient to stop chargebacks from occurring than to fight to get reimbursed later.

So how do you prevent chargebacks proactively? It starts with understanding the typical failure points in the vendor process and implementing robust strategies before the problems occur. Below, we outline the key areas to focus on, especially relevant for European vendors (who often face extra complexity with multi-country operations). By addressing each of these areas, you can dramatically reduce your chargeback incidents and keep more of your hard-earned revenue.

1. Strengthen Your Foundation: Terms, Agreements, and Amazon Programs

Consolidating shipments with Amazon’s PICS program helps reduce logistical complexity and even minimises chargeback risk by cutting down shipment errors and misrouted freight.

One of the first steps to proactive chargeback prevention is setting up the right terms and infrastructure with Amazon from the outset. This means negotiating vendor terms and using Amazon programs that inherently reduce the chance of errors. Key moves include:

- Leverage PICS (Pan-EU Inbound Consolidation Service): If you’re a European vendor shipping to multiple countries, consider enrolling in PICS. This program lets you send all your stock to one Amazon-designated warehouse (“injection point”), and Amazon handles distribution to various fulfillment centers. By cutting out dozens of separate shipments and differing local warehouse rules, you lower the odds of mistakes. PICS reduces complexity and has been shown to reduce chargebacks thanks to fewer touchpoints for error. (High-volume vendors might even explore SuperPICS, an enhanced version with a single EU hub and further consolidation for even greater efficiency.)

- Use Amazon’s Collect (WePay) Shipping Option: When setting up your freight terms, you typically have two choices: Prepaid (vendor pays) or Collect (Amazon pays). Under Collect – also called “WePay” – Amazon handles the carrier pickup and transport from your warehouse(khoocommerce.com). This shifts responsibility: once your pallets are picked up, Amazon is accountable for in-transit issues. If something goes wrong on the way to the fulfillment center (delays, lost shipment, etc.), Amazon can’t easily charge you a fee for it because they managed that leg. In contrast, under Prepaid (“TheyPay”), you arrange delivery and carry all risk until Amazon receives the goods(khoocommerce.com). Whenever feasible, opt for Collect (WePay) so Amazon’s logistics network carries more of the liability – this can automatically eliminate certain transportation-related chargebacks.

- Negotiate Favourable Vendor Terms: Don’t overlook the fine print of your Vendor Terms & Conditions. When possible, negotiate terms that reduce chargeback exposure. For example, add a clause that Amazon will not return unsold inventory (making returns Amazon’s responsibility – otherwise you might get hit with return shipping or prep chargebacks). Also, negotiate reasonable delivery windows or fewer ship-to locations if you have that leverage. Some vendors negotiate to limit the number of Amazon warehouses they must deliver to – Amazon sometimes allows a “preferred warehouse” (PICS) agreement where you deliver to, say, only 2 DCs instead of 5. With fewer facilities and clearer terms, you’ll have less chance to run afoul of differing warehouse requirements.

- Eliminate Known Pain Points Upfront: If there are known chronic issues in your partnership, address them in the agreement. For instance, if Amazon’s Poland and Czech Republic warehouses have unusually tight delivery windows or unique invoice processes, see if you can opt out of using those locations or get flexibility. Every additional handoff or special rule is a potential chargeback; streamlining these at the contract level can pay off.

By laying this groundwork, you create an environment where there are simply fewer opportunities for Amazon to levy chargebacks. It’s like removing traps from the field before you even start playing. Next, we’ll look at how to ensure your products and data are set up perfectly – another foundational element.

2. Optimise Product Setup, Data Accuracy, and Packaging Compliance

Many chargebacks occur because of mismatches between what Amazon expects and what you deliver. Product catalogue data and packaging are often at the root of these mismatches. To prevent these issues:

- Ensure Perfect Product Data & Carton Hierarchies: Double-check that your Vendor Central catalog data matches reality for each SKU. The “packaging hierarchy” (how many units per case, case dimensions/weight, etc.) must be accurate. If Amazon’s system thinks there are 24 units in a master carton because of old data, but you actually ship 20, you’ll get a Carton Content Accuracy chargeback for a content mismatch. Go through all your ASINs and make sure the “units per carton” and “cartons per pallet” fields, dimensions, weights, and other supply chain attributes are correct. This can be tedious, but you can use bulk item templates or flat-file uploads to speed it up. It’s worth the effort – when your data is clean, Amazon’s receive process will go smoothly and box content mismatches (a common chargeback) will almost vanish.

- Use One Barcode per Item (and per Carton as needed): A frequent labelling mistake is having multiple barcodes visible on a product or shipping box. Amazon’s scanners might pick up the wrong code, causing confusion. Each sellable unit should have only one scannable barcode (UPC/EAN) on its outer packaging, and that code should map to a single ASIN(amalytix.com). If you bundle units into a case that is itself a sellable SKU, that case needs its own unique barcode – don’t reuse the individual unit’s code on the case. Amazon explicitly warns that you may only use one barcode per unit, and never apply the same barcode to multiple boxes or products(amalytix.com). Audit your packaging: remove any extra old barcodes or codes meant for other retail channels. This includes eliminating stray QR codes or supplier codes that aren’t needed by Amazon. Clear, singular labeling prevents “unscannable barcode” or “labeling errors” chargebacks.

- Meet Amazon’s Packaging Requirements (e.g. SIOC/FFP standards): Amazon has detailed packaging guidelines, especially for the Ships In Own Container (SIOC) and Frustration-Free Packaging (FFP) programs. If your product is eligible to ship without Amazon adding a box, you must ensure the item’s packaging itself is robust enough for shipping. Generally, that means it should be a rigid, six-sided box with no exposed contents, capable of surviving courier handling(apasslab.com)(amalytix.com). For example, if you sell something like a badminton racket that currently comes in just a plastic bag, Amazon may require it to be boxed or otherwise certified for SIOC – otherwise you’ll get hit with prep chargebacks for “improper packaging”. In the SIOC program, vendors design their own e-commerce-ready packaging that can ship directly to customers without an Amazon over-box(amalytix.com). If you cannot provide that level of packaging (like in the racket example, there is no individual box), you either need to package it better or disable SIOC for that item so Amazon will box it (and avoid incurring non-compliance fees). Always review Amazon’s packaging prep matrix (e.g. requirements for poly bags, bubble wrap, etc.) for your product categories. Following those guidelines to the letter – sealing liquids, bagging plush items, bubble-wrapping fragile goods – will preempt many prep-related chargebacks(amalytix.com).

- Upload Documentation for Compliance (if needed): Certain products (hazmat, batteries, expiration-dated goods) require documentation or they’ll get chargebacks (e.g. missing expiry date on ASN). Make sure you’ve provided all necessary compliance docs (like exemption sheets, safety data sheets, expiration dates in the ASN) before shipping. This is part of product setup too – an often overlooked part – but critical for avoiding chargebacks in regulated categories.

In short, get your catalog and packaging “audit-ready”. If you pretend an Amazon employee was going to inspect your items and data for errors – would they find any? Clean it up now, and you’ll avoid those automated penalties later. The next step is to execute flawlessly when fulfilling POs.

3. Streamline Your Order Confirmation and Shipping Processes

Even with a perfect setup, things can go wrong during the actual fulfillment of Amazon’s purchase orders (POs). Proactive vendors establish processes to consistently ship what Amazon expects, on time, with all the right paperwork. Here’s how:

- Confirm POs Realistically – Don’t Over-commit: It’s exciting to get a big PO, but only confirm the quantities you can actually supply by the ship window. If Amazon orders 1000 units and you have only 800 available, confirm 800 (or confirm 1000 only if you have an imminent production batch to cover the rest). Over-confirming and then short-shipping triggers a chargeback for “Not filled” or a shortage claim. Amazon classifies a PO as “Not Filled” when the vendor fails to deliver the full confirmed quantity in time(khoocommerce.com). These are avoidable – be conservative and accurate in PO acknowledgements (POAs). Similarly, if you need to cancel or adjust down a quantity, do it ASAP (ideally before the shipping window starts). Amazon may penalise “Down Confirmed” changes made too late(khoocommerce.com). The goal is 100% PO accuracy: confirm what you will ship and ship what you confirmed.

- Plan for On-Time Delivery (Buffer the Delivery Window): Missing a delivery window is one of the most common chargebacks (often termed “Not on Time”)(khoocommerce.com). Amazon’s delivery windows in Europe can be very tight – sometimes a 30-minute unload slot at the DC. To avoid late delivery fees, build buffer time into your transport. Use reliable carriers (or Amazon’s partnered carriers via Collect). If you’re shipping cross-border in Europe, account for customs or border delays post-Brexit (ship a day earlier if needed for UK deliveries). It often helps to book Amazon appointments well in advance (especially if using Amazon’s Carrier Central). Pro tip: under the Collect/WePay model, Amazon is responsible for pickup scheduling – meaning if their truck is late or misses the slot, it’s on Amazon. This again highlights the benefit of Amazon-managed freight in reducing late-delivery chargebacks.

- Prepare Complete and Correct Shipping Docs (ASN, BOL, Labels): Every Amazon PO shipment must have an Advance Shipment Notification (ASN) submitted, usually through Vendor Central or EDI, and each pallet/carton needs proper labels (like the SSCC carton codes). Ensure your ASN exactly matches what is shipped – item counts, pallet counts, carrier info, and tracking (PRO/BOL numbers) must align. A common chargeback is “ASN Accuracy”, which covers PRO/BOL mismatches or unit count mismatches(khoocommerce.com). Double-check that the BOL number you enter in the ASN matches the actual BOL from the carrier, and that all pallet labels (License Plate labels) are affixed and scannable. Also include a physical packing list/BOL with the shipment for the Amazon dock team, and have the driver sign and timestamp copies as proof of delivery. Missing or incorrect paperwork can lead to fees, so get this documentation right every time.

- Follow Carton and Pallet Guidelines: Amazon has specific rules for carton weight and size (e.g. usually max 50 lb/23 kg per box unless it's an oversized item) and pallet configuration (height limits, no mixed SKUs unless labelled, etc.). Oversized or overweight cartons may incur chargebacks(khoocommerce.com). Train your warehouse team to pack to Amazon’s standards: no heavy cartons over the limit, no mixed items in a carton unless allowed, all boxes/pallets labelled clearly. If you receive a routing instruction (for example, to send certain units to a Czech warehouse), make sure to palletise and label exactly as instructed. Little details like pallet height or using non-approved pallet types can result in rework fees.

- Enforce a “No Surprises” Policy at the Dock: Ultimately, when Amazon opens your delivery truck, everything should be as expected: the right number of pallets, correct labels, and within the appointment time. Strive for that level of execution. If a truck gets stuck in traffic and will miss the slot, proactively communicate and reschedule if possible, rather than just showing up late (which would be a chargeback for a no-show or late arrival). These operational disciplines ensure Amazon’s receiving process is smooth – meaning no chargeback gets triggered.

By tightening up these fulfillment processes, you can prevent many operational chargebacks like late delivery, no-show, or carton info errors before they happen. It’s all about being proactive and detail-oriented from the moment you accept a PO to the moment Amazon scans your pallet in.

4. Establish Clear Ownership and SOPs for the Amazon Process

One recurring theme in successful vendor operations is strong internal organisation. Chargeback prevention isn’t just an isolated task; it’s a coordinated effort across catalogue managers, warehouse staff, and account managers. To foster this:

- Assign an “Amazon Captain” internally: Designate one person (or a small cross-functional team) to own the end-to-end Amazon vendor process. This Amazon lead keeps the big picture in mind – from catalogue setup to logistics to chargeback monitoring. They will ensure nothing falls through the cracks between departments. For example, if the warehouse is prepping a shipment, the Amazon captain makes sure they have the latest packing requirements and that the ASN is filed. If new chargeback codes show up, this person investigates why and liaises with the right team to fix the root cause. Having clear ownership prevents the common scenario of “everyone thought someone else was handling it.”

- Document Standard Operating Procedures (SOPs) for everything: Every time you encounter a chargeback scenario, create an SOP to avoid it in the future. If something happens twice, it should have an SOP. For instance, if you got dinged for “Missing carton label,” your SOP might dictate that the warehouse must photograph each pallet’s labels before dispatch and a coordinator verifies all labels are present. If a short shipment happened because of inventory miscount, institute an SOP that inventory availability is double-checked against the PO before confirmation. By writing these processes down (in a manual or using a visual flowchart tool like Miro), training the team, and updating them whenever Amazon policies change, you bake compliance into daily operations. Many vendors fail because they treat chargebacks ad hoc – instead, systematise the lessons so you don’t repeat mistakes.

- Educate and empower your teams: Make sure your logistics team has actually read the relevant sections of Amazon’s Vendor Manual (yes, the big one inside Vendor Central!). It’s dense, but it contains packaging rules, shipping rules, and prep requirements that those on the ground need to know. Similarly, your catalogue/content team should know the importance of accurate data as discussed, and your finance team should understand the chargeback codes on remittances. Cross-train teams on the basics of Amazon operations so they understand why these SOPs matter. When everyone from the e-commerce manager to the warehouse picker is aware of Amazon’s standards, they become stakeholders in preventing errors.

- Centralised Communication: Use a shared dashboard or regular meeting to review Amazon operational performance. If a chargeback does occur, discuss it openly: what caused it, how to prevent it next time. Create a culture where the goal is zero chargebacks, and the whole team is accountable to that goal. Over time, as SOPs take hold, you’ll see the chargeback count drop and stay low.

Simply put, proactive chargeback management is as much about people and process as it is about technical requirements. When your organization treats Amazon logistics with the same care as, say, product quality or customer service, the results (fewer errors and fees) will follow.

5. Monitor Metrics and Continuously Improve

Even with great processes, you should continuously monitor your performance and Amazon’s feedback – this helps catch any slip-ups early and identify new improvement opportunities:

- Track Your Chargeback Reports: In Vendor Central, regularly check the Claims > Operational Performance or Chargebacks section. Amazon provides details on each chargeback event, the reason code, and financial impact. Use these reports like a scorecard. Many vendors export the data (you can download up to ~22 months of history) and analyse it in Excel or a BI tool. Look for trends: are certain ASINs or warehouses causing most issues? For example, you might find Chargebacks cluster around a few specific ASINs – that’s a clue those product setups or packagings need attention. Or you might see repeated issues at one FC, indicating maybe that FC has special rules you missed or chronic carrier delays to that location. By identifying the 20% of causes that create 80% of your chargebacks, you can target your fixes effectively.

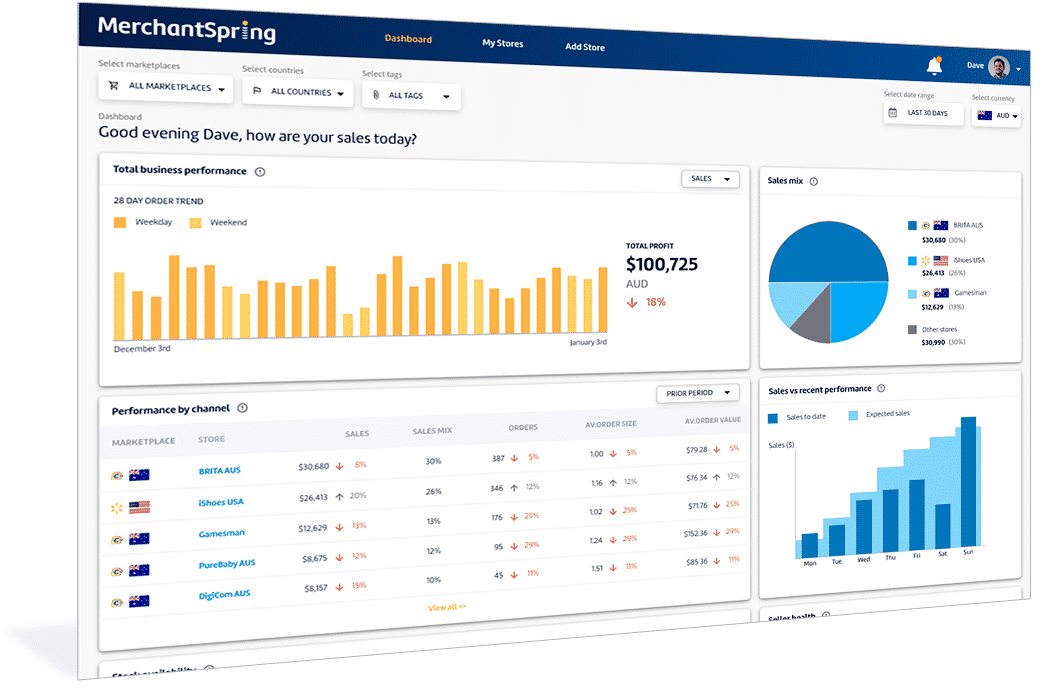

- Leverage Analytics Tools (if available): Manually tracking in Vendor Central can be cumbersome. Consider using vendor analytics tools (like MerchantSpring’s dashboard or others) that aggregate chargeback metrics. These can give you a cleaner view of your on-time performance, ASN accuracy rate, etc., and even alert you when something deviates. The key is to not be in the dark – make chargeback metrics as visible as sales metrics. If your on-time performance drops or chargeback rate creeps up above, say, 1% of shipments, you want to know immediately and respond.

- Verify Amazon’s Settings (MOQs and more): Amazon’s systems sometimes override settings like Minimum Order Quantity (MOQ) for POs. If you negotiated or set an MOQ (minimum units Amazon must order in one go), keep an eye that it’s being honored. In practice, you set MOQ per ASIN per fulfillment center through Vendor Central or via your Amazon buyer, but Amazon may switch warehouses or “forget” the MOQ after some time. If you notice Amazon placing tiny POs (e.g., ordering 2 units when your MOQ is 10), reach out to Vendor Support or your vendor manager to correct it. Regularly audit these settings, especially after any Amazon system updates or annual terms negotiations. Ensuring Amazon orders in economical quantities saves you from the hassle and cost of frequent small shipments.

- Keep Abreast of Policy Changes: Amazon often updates packaging, shipping, or compliance policies (for example, new sustainability requirements, barcode policy changes, or programs like SIOC being rebranded to SIPP). Stay informed via Amazon Vendor news, webinars, or agency newsletters. Adapting quickly to policy changes is vital – you don’t want to discover a new rule only after chargebacks hit. For instance, if Amazon lowers the weight threshold for an overweight carton chargeback in the EU, proactively adjust your warehouse SOP to the new limit.

- Conduct Periodic Internal Audits: Every quarter or so, do an internal “audit” of a sample shipment: Was the ASN 100% accurate? Were labels perfect? Did Amazon check-in without issues? This kind of spot-check can catch complacency. Also, review if any chargebacks were successfully disputed – if Amazon accepted your dispute, figure out how to avoid that scenario altogether moving forward (maybe the dispute reason was a one-time glitch, or maybe it reveals something you can improve).

Continuous improvement is an ongoing loop. Monitor – Detect – Fix – Repeat. Over time, this will drive your operational defects down to a minimum. Not only will you save money on fewer chargebacks, but you’ll likely see smoother operations and better in-stock rates (since fewer shipments get delayed or flagged). It’s a win-win for efficiency and profitability.

6. Tackle Regional Complexities (European Vendors Take Note)

Operating as a vendor in Europe brings some extra challenges, but with proactive management you can turn these into non-issues:

- Harmonise Multi-Country Operations: If you sell across multiple European marketplaces (UK, DE, FR, IT, ES, etc.), you may be dealing with different Amazon entities and fulfillment centers. Each country might have local packaging laws (language on labels, recycling logos) and Amazon may send POs from different country vendor portals. A pro tip from experienced vendors: consider centralising your Amazon vendor account for Europe. If possible, funnel POs for all EU countries through one vendor account or at least ensure all your country accounts have identical terms and product data. This prevents Amazon from, say, ordering product from your French entity (because it has a slightly lower cost price) to supply Germany – which complicates your logistics and can lead to unexpected cross-border shipments (and potential chargebacks for longer transit or customs hiccups). By aligning terms and using programs like Pan-EU PICS, you encourage Amazon to order in a consolidated way. This reduces cross-border complexity, multiple invoices, and chances for error.

- Mind Brexit and UK Separations: Post-Brexit, UK is its own market. If you participate in Amazon EU unified vendor program, ensure you’ve set up separate UK arrangements or use Amazon’s Direct Import or EFN (European Fulfillment Network) wisely. Shipping to UK now involves customs and often Amazon UK POs are separate. Plan for a bit more lead time and paperwork to UK to avoid late deliveries. Some vendors pre-position stock in Amazon EU vs UK to avoid trans-channel delays. Being proactive about these geopolitical wrinkles will save you from “shipment late” or customs-related chargebacks.

- Adapt to Country-Specific Rules: Within the EU, Amazon might have warehouse-specific quirks – e.g. the CZ and PL fulfillment centers often used for EU distribution have very short delivery windows and strict booking procedures. If you’re required to send goods there, be extremely diligent with booking the appointment as soon as the PO arrives (some vendors noted windows as short as 24-48 hours). Similarly, Southern European FCs might not accept certain pallet types (some require Euro pallets). Keep a cheat-sheet of any local requirements and include these in your SOPs depending on destination. By respecting each country’s nuances proactively, you’ll avoid most compliance issues. Remember, the goal is to make every delivery “boringly perfect” no matter where it’s going.

In summary, Europe’s complexity is manageable if you simplify and standardise wherever you can (via consolidation programs and unified accounts), and meticulously follow each region’s requirements where you can’t simplify. Many top vendors operate across 5-10 countries successfully by centralising control and being detail-oriented – you can too.

7. Know When to Seek Help (AVS or External Services)

While the focus here is on doing it in-house, it’s worth noting the role of additional support:

- Amazon Vendor Services (AVS): AVS, also known as Amazon Premium Services or Vendor Managers, is essentially a paid Amazon account manager service. An AVS manager can assist with things like expediting catalogue fixes or investigating chargebacks internally. However, AVS comes at a hefty cost (often 3-5% of your COGS as a fee) and not all vendors qualify for it(wakecommerce.co.uk). In recent years, Amazon has reduced the availability of AVS for smaller vendors. If you’re a very large vendor with hundreds of ASINs and chronic issues that you can’t solve alone, AVS might help escalate problems (for example, getting Amazon’s receiving team to resolve an ASN discrepancy that is repeatedly not your fault). But for most vendors, the strategies we’ve outlined will address the major pain points without needing AVS. Think of AVS as a last resort or a luxury – nice to have if included in your terms, but not a substitute for strong internal processes.

- Chargeback Recovery Services: There are agencies and tools that specialize in disputing Amazon chargebacks on your behalf, recovering funds where possible. These can be useful to recoup money, but note that disputing is reactive. If you’ve followed the guide so far, hopefully you won’t have many chargebacks to dispute! That said, it may be worthwhile to do a one-time audit with such a service or use a tool (some vendors use tools like ProfitGuard or others(wakecommerce.co.uk) to ensure you haven’t missed legitimate disputes. Just remember: the real win is to prevent the chargeback, not just recover it.

- Consultants or Agencies: Bringing in an Amazon vendor consultant or agency (like ama-X, or others) can inject expert perspective into your operations. They might help map out your processes, identify obscure causes, or train your team. If you’re really struggling despite trying the above steps, an experienced third party could pinpoint issues faster. For example, they might notice, “Oh, your EDI integration is sending ASNs incorrectly – fix that and 80% of your chargebacks disappear.” Use external help strategically to accelerate your learning curve, but be wary of any that promise magic bullets without fixing root causes.

In essence, most vendors can master chargeback prevention internally with diligence and the right knowledge. Outside help is available, but should complement your internal efforts, not replace them.

Conclusion: Turn Chargeback Challenges into Opportunities

Amazon chargebacks don’t have to derail your success as a vendor. By taking the proactive measures outlined above, you can drastically reduce – or even virtually eliminate – those annoying fees. More importantly, each area of improvement (better data accuracy, better packaging, tighter logistics) will have side benefits like smoother operations and happier Amazon buyers. You’ll protect your margins and can reinvest those saved dollars (or euros) into growing your business rather than paying for avoidable mistakes.

The big mindset shift is moving from a reactive stance (“Oh no, a chargeback happened, how do we fight it?”) to a preventative stance (“What can we improve so that a chargeback never happens in the first place?”). As we’ve discussed, prevention truly is the best cure – not only do you avoid the fee, you avoid the inefficiency or defect that caused it, leading to a stronger supply chain.

In the words of one expert, chargebacks often get brushed off as a cost of doing business, but that mindset just drains profit(linkedin.com). Instead, addressing the root causes proactively turns chargebacks into an opportunity to sharpen your operational excellence. Over time, you might even start seeing Amazon’s chargeback report as a badge of honour – empty, or close to it, month after month – indicating your vendor machine is running in top form.

Finally, remember that Amazon’s requirements will evolve. Stay informed, keep your team trained, and update your SOPs regularly. If you do that, you’ll stay ahead of the curve and keep those chargebacks at bay. Here’s to protecting your profits and strengthening your Amazon vendor partnership through smart, proactive strategies!

-Aug-04-2025-03-34-26-7813-AM.png)

Add a Comment